Products Used in BOAC Aircraft Maintenance:

- Sifbronze No. 1 Rods: Used for welding test rig apparatus, couplings, unions, and hydraulic tubes in aircraft systems, particularly in the thrust-reversal units of the Boeing 707 and Comet Jetliner.

- Sifsteel No. 20 Welding Rods: Employed for various stainless-steel applications and routine aircraft maintenance, providing strength and precision.

- Test Rig Apparatus: Specialized equipment used to test and simulate operational conditions of aircraft components after repairs or modifications.

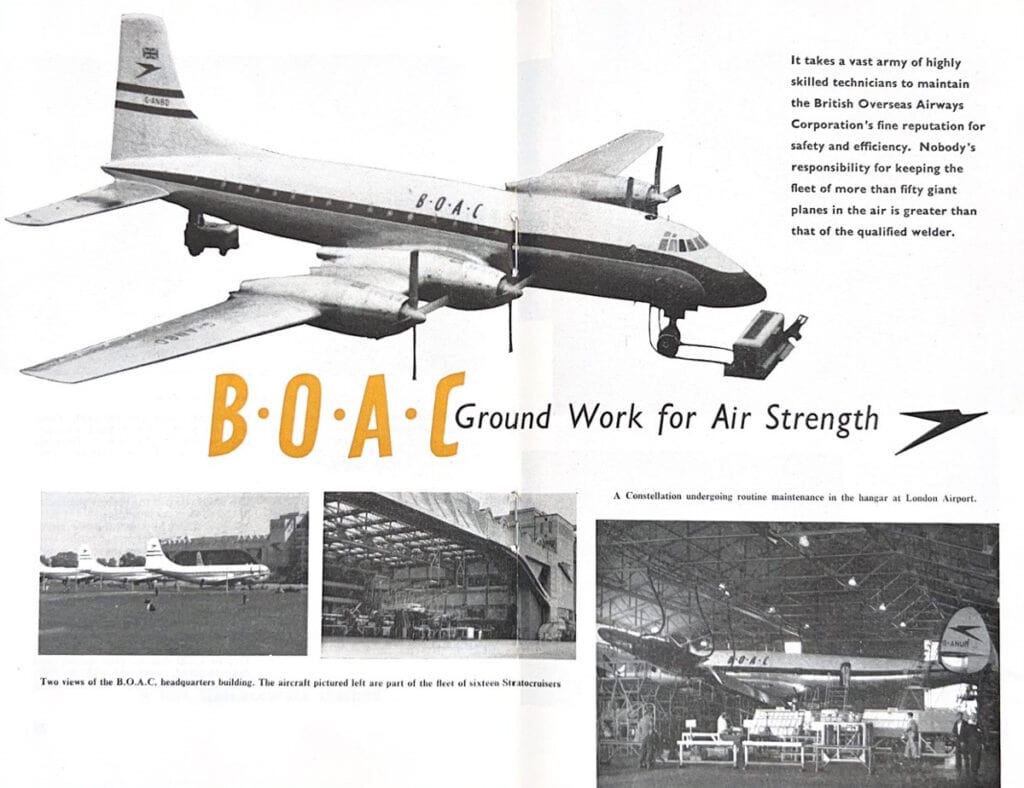

British Overseas Airways Corporation (BOAC) was a key player in the evolution of international air travel, renowned for its advanced fleet and meticulous engineering standards. Critical to BOAC’s operational success was the support from SIF (Speciality Industrial Fabrications), particularly in the areas of maintenance and component repair through the provision of high-quality welding materials.

Background of BOAC

BOAC, established in 1939 through the merger of Imperial Airways and British Airways Ltd, served as the primary British long-haul airline until its merger with British European Airways in 1974, forming British Airways. Throughout its existence, BOAC was at the forefront of aviation technology, operating iconic aircraft such as the Comet 4s, Bristol Britannias, and Boeing 707s. The airline’s commitment to safety, reliability, and passenger comfort was underscored by rigorous maintenance protocols and innovative engineering solutions.

SIF’s Contribution to BOAC

Engineering Maintenance and Safety

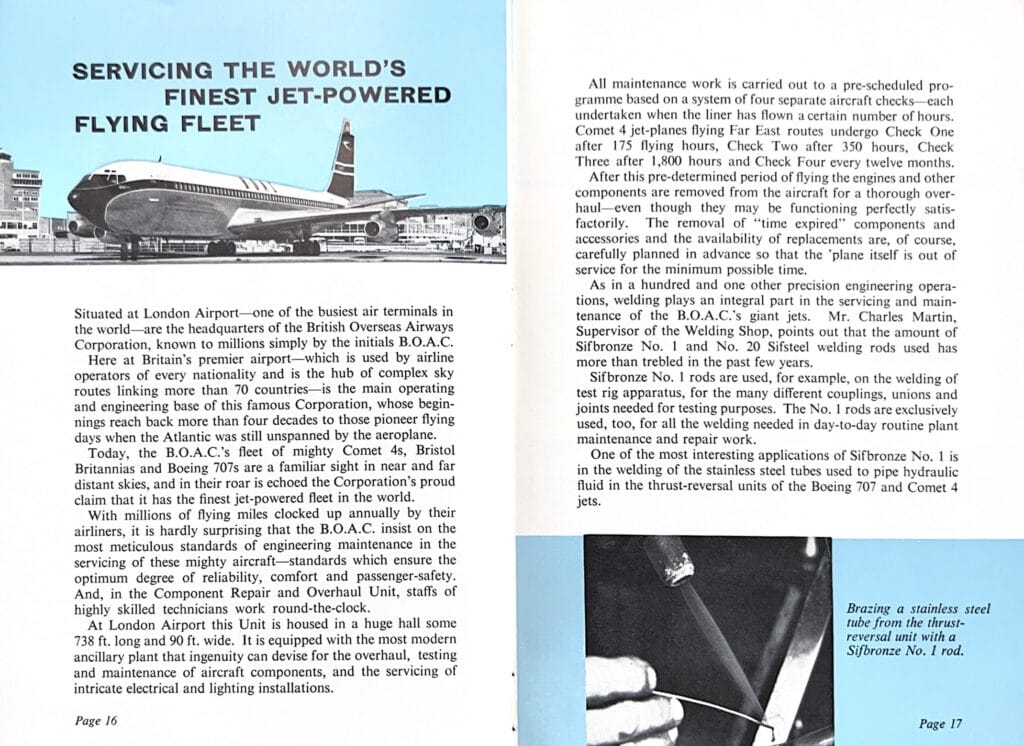

- Maintenance Protocols: BOAC’s stringent maintenance program required regular checks and overhauls of aircraft components. SIF provided essential materials like Sifbronze No. 1 and No. 20 Sifsteel welding rods, which were critical in ensuring the durability and reliability of these components.

- Welding Expertise: The welding shop, supervised by Charles Martin, utilized Sifbronze rods extensively. These rods were integral in the maintenance and repair of various aircraft parts, from test rig apparatus to day-to-day plant maintenance.

- Component Overhaul: BOAC’s meticulous overhaul procedures, including the removal and replacement of “time-expired” components, relied heavily on the availability of reliable welding materials. SIF’s products ensured that these components could be serviced to the highest standards, minimizing aircraft downtime.

Specific Applications

- Hydraulic Systems: One notable application of Sifbronze No. 1 was in the welding of stainless steel tubes for the hydraulic systems in the thrust-reversal units of Boeing 707 and Comet 4 jets. This application was crucial for the performance and safety of the aircraft’s reverse thrust capabilities.

- Electrical and Lighting Installations: SIF’s welding rods were also used in the maintenance of intricate electrical and lighting installations, ensuring that these systems met the high safety and reliability standards required for aviation operations.

Impact on BOAC’s Operations

Enhanced Reliability and Safety

- Operational Efficiency: By providing high-quality welding materials, SIF enabled BOAC to maintain a high standard of engineering maintenance, directly contributing to the airline’s reputation for reliability and safety.

- Passenger Comfort: The reliability of BOAC’s aircraft, supported by rigorous maintenance and high-quality materials from SIF, ensured a comfortable flying experience for passengers, enhancing the airline’s reputation and customer satisfaction.

Technological Advancement

- Pioneering Jet Age: BOAC’s fleet of jet-powered aircraft, including the Comet 4 and Boeing 707, represented the cutting edge of aviation technology. SIF’s materials were vital in maintaining these advanced aircraft, helping BOAC lead the transition into the jet age.

- Innovation in Maintenance: The use of advanced welding materials and techniques, facilitated by SIF, allowed BOAC to implement innovative maintenance practices that set new standards in the aviation industry.

Conclusion

SIF’s support through the provision of high-quality welding materials was a cornerstone of BOAC’s operational success. By ensuring the reliability and safety of critical aircraft components, SIF played an indispensable role in helping BOAC maintain its reputation as a leader in international air travel. This partnership highlights the importance of specialized industrial support in the advancement and maintenance of aviation technology, ultimately contributing to the evolution of modern long-haul air travel.

And at the bottom can you add these Links under references:

- BOAC: https://www.aerosociety.com/media/4844/british-overseas-airways-corporation-1940-1950-and-its-legacy.pdf

- London Airport: https://www.heathrow.com/company/about-heathrow/our-history

- Sifbronze No. 1 Rods: https://weldability-sif.com/products/sif-consumables/ro011650/

- Sifsteel Welding Rods: https://weldability-sif.com/products/sif-consumables/ro111650/