Introduction

In the bustling industrial town of West Thurrock, Essex, a sprawling 72,000-square-foot facility stood as a testament to innovation and precision. This was the Co-operative Wholesale Society’s Dairy Equipment Works, a hub of activity where stainless steel vessels of all shapes and sizes were crafted to perfection. From humble beginnings, this factory grew to become a key player in the dairy equipment industry, producing vessels with capacities up to 10,000 gallons. Central to their success was the utilization of advanced welding techniques and materials, where the Suffolk Iron Foundry (SIF) played an indispensable role.

The Industrial Challenge

The demand for high-quality stainless steel dairy equipment was on the rise, driven by the growing dairy industry’s need for reliable and durable storage solutions. The Co-operative Wholesale Society’s Dairy Equipment Works faced the challenge of producing a wide variety of vessels, each requiring precise fabrication and welding to meet stringent industry standards.

The Role of Welding in Dairy Equipment Fabrication

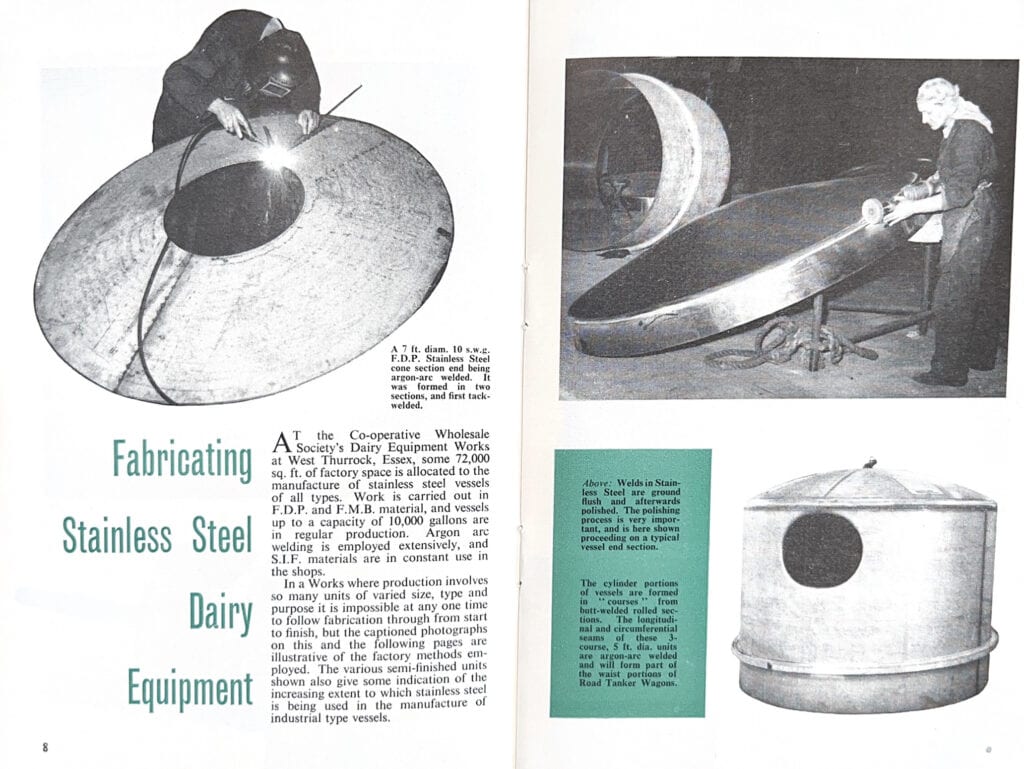

The manufacturing process at the West Thurrock facility was meticulous. Using F.D.P. and F.M.B. materials, the factory churned out a diverse range of stainless steel vessels. The process began with forming large sections of stainless steel, followed by tack-welding to hold the pieces in place. One notable example was a 7-foot diameter, 10 s.w.g. stainless steel cone-section, initially tack-welded before undergoing argon-arc welding.

The Importance of Argon-Arc Welding

Argon-arc welding, a technique prized for its precision and strength, was extensively employed throughout the factory. This method ensured that the welds were clean, strong, and durable, essential for the integrity of vessels that would store large volumes of dairy products. After welding, the joints were meticulously ground flush and polished, highlighting the importance of the polishing process in ensuring both the functionality and aesthetic quality of the equipment.

The Critical Support from Suffolk Iron Foundry

The success of these welding processes hinged on the materials and equipment used. This is where Suffolk Iron Foundry (SIF) made a significant impact. SIF’s welding materials were renowned for their quality and reliability. By providing high-grade welding rods and equipment, SIF ensured that the Co-operative Wholesale Society’s Dairy Equipment Works could achieve the highest standards of precision and durability in their products.

Historical Significance: The Manufacturing Process

The fabrication process involved creating cylinder portions of vessels from bit-welded rolled sections. These sections were joined using argon-arc welding along longitudinal and circumferential seams. The 3-course, 5-foot diameter units, which would become part of the road tanker wagons, demonstrated the factory’s capability to produce complex and large-scale equipment efficiently.

The partnership with SIF was crucial in maintaining the consistency and quality of the welds. The SIF materials used in the welding processes not only enhanced the strength of the joints but also reduced the likelihood of defects, which was vital for the longevity and safety of the dairy equipment.

Visual Insights and Increasing Use of Stainless Steel

Photographs from the period illustrate the factory methods employed, showcasing the various semi-finished units in different stages of production. These images provide a glimpse into the meticulous processes that went into manufacturing industrial type vessels. They also underscore the increasing reliance on stainless steel, a material valued for its corrosion resistance and durability, which was becoming essential in the production of high-quality dairy equipment.

Conclusion

The story of the Co-operative Wholesale Society’s Dairy Equipment Works is one of industrial prowess and innovation. Their ability to produce a vast array of stainless steel vessels with impeccable precision was a direct result of their advanced welding techniques and the superior materials provided by Suffolk Iron Foundry.

This historical case study not only highlights the remarkable achievements of the factory but also the pivotal role played by SIF in supporting their endeavors. Through their collaboration, they set new standards in the dairy equipment industry, ensuring that the products were not only functional and reliable but also exemplified the highest levels of craftsmanship.

The partnership between the Co-operative Wholesale Society’s Dairy Equipment Works and Suffolk Iron Foundry stands as a testament to the power of collaboration and innovation, showcasing how industrial excellence can be achieved through the seamless integration of advanced materials and meticulous manufacturing processes.