Introduction

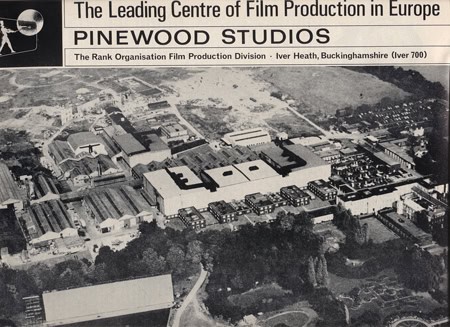

The magic of cinema has captivated audiences for generations, whisking them away to fantastical worlds and breathtaking adventures. While viewers are engrossed in the on-screen spectacle, few ponder the intricate craftsmanship behind the scenes. This case study delves into the vital, yet often overlooked, role of the J. Arthur Rank Film Studios at Pinewood, highlighting how their innovative use of mobile rostrums, supported by the superior welding techniques of Suffolk Iron Foundry (SIF), revolutionized film production.

The Challenge of Creating Movie Magic

Creating the stunning scenes that grace the silver screen requires a tremendous amount of behind-the-scenes work. The J. Arthur Rank Film Studios, a cornerstone of British cinema, faced the continuous challenge of constructing versatile and reliable sets that could transform quickly and efficiently. Traditional set-building methods were cumbersome and time-consuming, necessitating a more flexible and robust solution.

Enter the Mobile Rostrum

To address these challenges, the studios introduced the mobile rostrum—an outstanding modern development in film production. These tubular structures were designed to be light yet immensely strong, capable of forming a twenty-foot square platform. The rostrums could be raised or lowered to any height or angle and configured in various shapes to accommodate the diverse demands of film sets, from rustic country lanes to opulent ballrooms.

The Crucial Role of Welding

The success of these rostrums depended heavily on the quality of their construction, particularly the welding of their tubular joints. The J. Arthur Rank Film Studios turned to Suffolk Iron Foundry (SIF) for their expertise in welding technology. The Sifbronze Process, developed by SIF, was chosen as the welding medium due to its unparalleled reliability and strength. This method ensured that the tubular joints were not only sound but also maintained perfect alignment, crucial for the stability and versatility of the rostrums.

The Sifbronze Advantage

The Sifbronze Process provided several advantages that were critical to the success of the rostrums. It produced welds that were strong and durable, capable of withstanding the constant adjustments and reconfigurations required on set. Moreover, the process ensured that the welds were clean and precise, minimizing the risk of structural failures that could disrupt filming schedules and compromise safety.

Historical Significance: Transforming Film Production

The integration of SIF’s welding technology into the construction of mobile rostrums marked a significant milestone in the history of film production. It allowed for greater flexibility and efficiency in set design, enabling filmmakers to create more complex and dynamic scenes with ease. The ability to quickly adjust and reconfigure the rostrums meant that elaborate sets could be constructed, modified, and dismantled in record time, significantly enhancing the studio’s productivity.

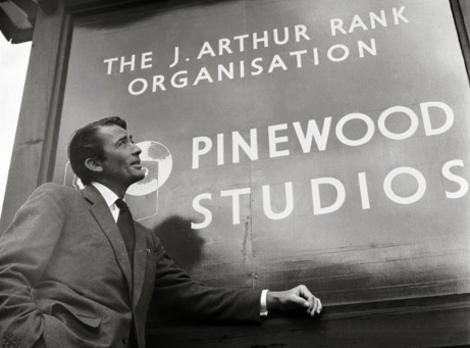

A Visit to Pinewood

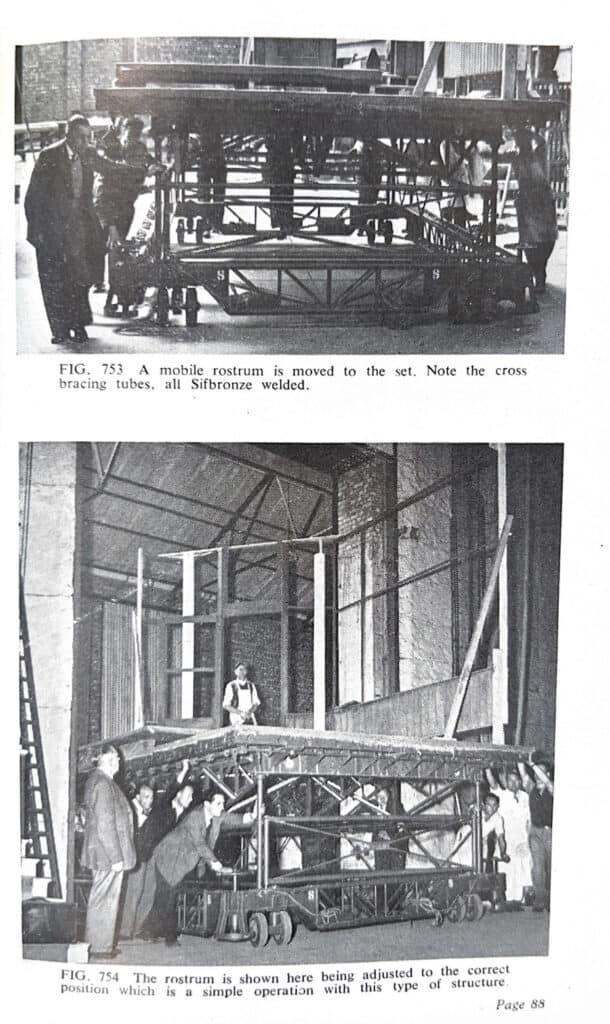

During a visit to the J. Arthur Rank Film Studios at Pinewood, observers were struck by the seamless operation of the mobile rostrums. Photographs from the period showcase these structures being moved across the studio floor, with their tubular cross bracing clearly visible. Practically all these tubular joints were Sifbronzed, a testament to the reliability and effectiveness of the welding process.

One image captures a mobile rostrum being adjusted to the correct position—a task made simple by the innovative design and robust construction of the structure. These visual records highlight the critical role of high-quality welding in ensuring the functionality and versatility of the equipment used in film production.

Conclusion

The story of the J. Arthur Rank Film Studios and their pioneering use of mobile rostrums is a testament to the ingenuity and craftsmanship that underpin the magic of cinema. The support from Suffolk Iron Foundry, through their advanced Sifbronze welding process, was instrumental in transforming the way film sets were constructed and managed.

This historical case study celebrates the unsung heroes behind the scenes—the welders and engineers whose expertise and dedication made it possible for filmmakers to bring their visions to life. Through their collaboration, the J. Arthur Rank Film Studios and SIF set new standards in the film industry, ensuring that the enchantment of the silver screen continues to captivate audiences for generations to come.

- References –

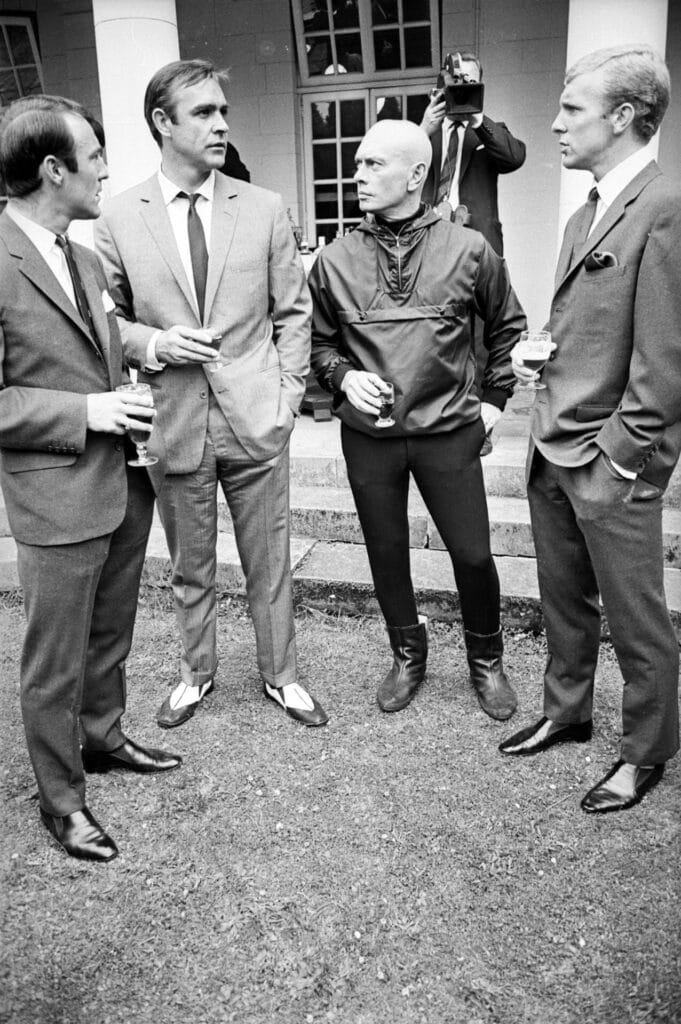

- Pinewood Studios 1966, (Sean Connery and Yul Brynner, flanked by footballers Jimmy Greaves and Bobby Moore) – https://flashbak.com/pictures-of-sean-connery-1930-2020-433987/pinewood-studios-1966-sean-connery-and-yul-brynner-flanked-by-footballers-jimmy-greaves-and-bobby-moore/

- pinewood sign – https://nzpetesmatteshot.blogspot.com/2014/03/movie-magic-at-rank-organisation.html

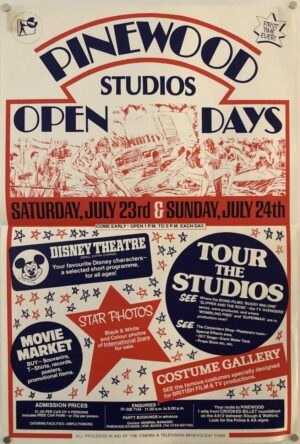

- Pinewood Studios Open Days – https://bluerobincollectables.com/shop/pinewood-studios-open-days/

- Pinewood Magazine Ad – https://tvstudiohistory.co.uk/londons-film-studios/pinewood-studios/

- Pinewood Newspaper Ad 1965 – https://cinemaretro.com/index.php?/archives/10591-DISNEY-SIGNS-LONG-TERM-DEAL-WITH-PINEWOOD-STUDIOS.html

- PINEWOOD FILM STUDIOS OPEN DAY – COLOUR – https://www.youtube.com/watch?v=wO-vmGUIVyc

- Article Links –

- A History of Bringing Dreams to Life – https://pinewoodgroup.com/pinewood-today/our-heritage

- Making Film History for over 80 years – https://pinewoodgroup.com/explore-pinewood/for-historians

- Pinewood Studios – https://tvstudiohistory.co.uk/londons-film-studios/pinewood-studios/

- 75 years of Pinewood Studios – https://www.theguardian.com/theguardian/from-the-archive-blog/2011/sep/30/pinewood-studios-75-years-anniversary