In the late 1960s, the automotive world was abuzz with the anticipation of a new model that promised to blend style, performance, and affordability: the Ford Capri. This car was envisioned as the European answer to the American Mustang and aimed to capture drivers’ hearts across the continent. Behind its sleek design and versatile performance, a significant part of its success was due to the innovative manufacturing techniques and materials used in its production. A pivotal player in this story was the Suffolk Iron Foundry (SIF), whose contributions were integral to the Capri’s acclaim.

The Genesis of the Ford Capri

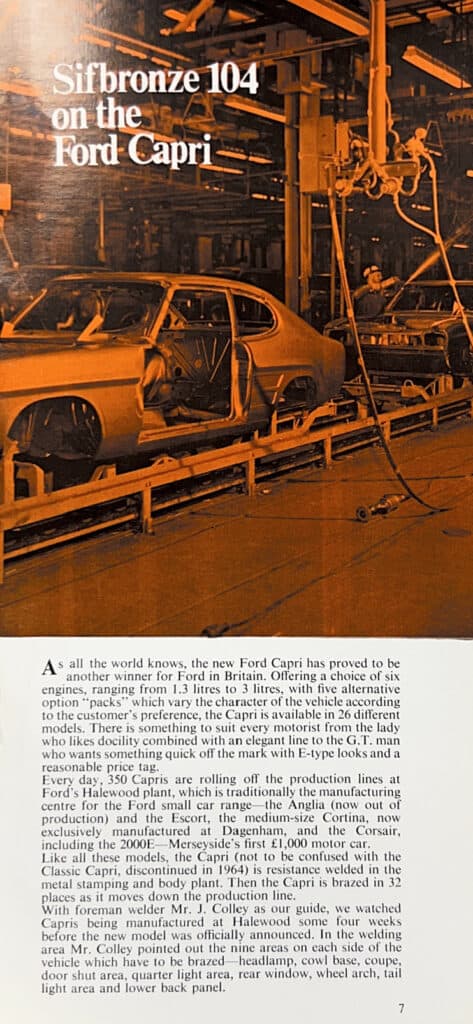

As the 1960s drew to a close, Ford sought to create a vehicle that would appeal to many customers. The Capri was designed with six engines, ranging from 1.3 to 3 litres, and offered in 26 different models. This variety allowed Ford to cater to everyone from the leisurely driver to the GT enthusiast seeking a quick, stylish ride.

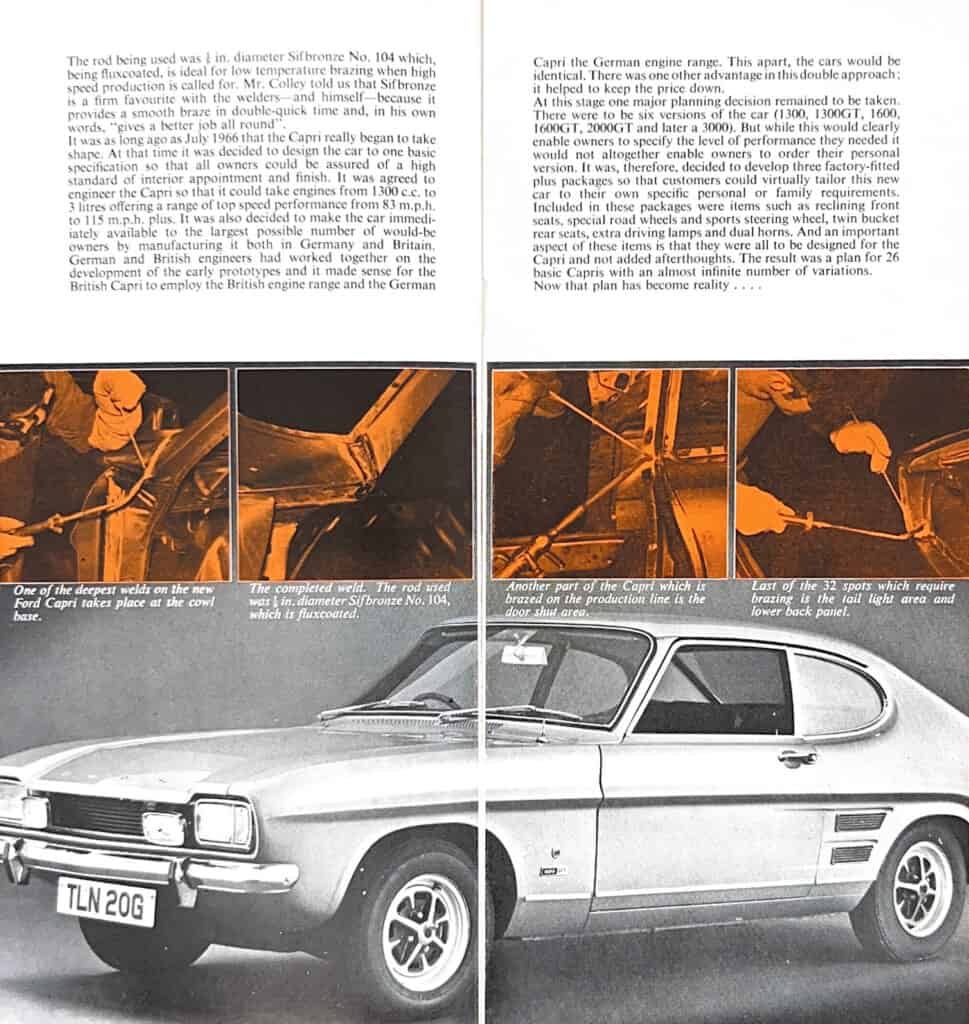

The production of the Capri was a mammoth task, with 350 units rolling off the assembly line daily at Ford’s Halewood plant. This facility had a rich history of producing iconic Ford models, such as the Anglia and the Escort. However, manufacturing the Capri required a new level of precision and innovation, particularly in welding and brazing.

Enter Suffolk Iron Foundry

Suffolk Iron Foundry, known for its high-quality metalwork and innovative products, was a key supplier to the automotive industry. For the Capri, SIF provided a critical component: the Sifbronze No. 104 brazing rod. This 1-inch diameter, flux-coated rod was ideal for low-temperature brazing, a crucial technique for the Capri’s high-speed production requirements.

Foreman welder Mr J. Colley highlighted the importance of Sifbronze No. 104, noting its popularity among welders for its ability to quickly produce smooth, reliable brazes. The rod’s efficiency was not just a matter of convenience but a necessity to keep up with the rigorous demands of the production line.

The Brazing Process and Its Importance

Resistance welding and brazing were fundamental to the Capri’s assembly. The car was welded in the metal stamping and body plant before being brazed in 32 critical spots as it moved down the production line. These spots included areas around the headlamp, cowl base, door shut area, quarter light area, rear window, wheel arch, tail light area, and lower back panel.

SIF’s Sifbronze No. 104 played a vital role in this process. Its low-temperature capabilities meant that it could be used efficiently without compromising the car’s structural integrity. This was especially important given the diverse range of Capri models and the need for consistent quality across each unit.

Innovation and Collaboration

The development of the Capri was a collaborative effort between British and German engineers, aiming to create a car that could be manufactured in both countries with identical standards. This transnational effort was facilitated by SIF’s reliable materials, which ensured that the manufacturing processes could be replicated accurately regardless of location.

By July 1966, the Capri’s design had taken shape. Ford’s decision to engineer the Capri to accommodate engines from 1300 c.c. to 3 liters highlighted the versatility and foresight in their planning. The inclusion of Sifbronze No. 104 in the production process was a testament to SIF’s reputation for quality and reliability.

Legacy and Impact

The Ford Capri became a symbol of affordable performance and stylish design. Its success was due in no small part to the behind-the-scenes contributions of companies like Suffolk Iron Foundry. By providing materials that met the demanding requirements of modern automotive manufacturing, SIF ensured that the Capri could be produced efficiently and to a high standard.

In retrospect, the story of the Ford Capri is not just about a car but about the synergy between innovation, craftsmanship, and industrial collaboration. Although not always highlighted, SIF’s role was crucial in bringing the Capri to life and setting a standard for future automotive projects. The Capri’s legacy as a beloved classic car is a tribute to the seamless integration of quality materials and visionary design.

httpshttps://youtu.be/fnCXiv1cVdg://youtu.be/fnCXiv1cVdg

https://www.getreading.co.uk/news/reading-berkshire-news/gallery/ford-capri-launch-dennis-j-11994102

- References –

- Ford Capri Advert – https://dk.pinterest.com/pin/294071050660423228/

- 1961_car – https://www.adrianflux.co.uk/cult-classics/ford-capri-its-rise-fall-and-rise-again/

- Ford capri adverts – https://www.youtube.com/watch?app=desktop&v=J_rVkDvB1TE

- Ford Capri Adverts 1970’s and 80’s – https://www.youtube.com/watch?v=sfgnx3EfEJQ

- Produktion Ford Capri MK1 1970 – https://www.youtube.com/watch?v=eaYdH1ziLAc

- Model Catalogue – https://www.ebay.co.uk/itm/293229151050

- Article Links –

- Cult classics – https://www.adrianflux.co.uk/cult-classics/ford-capri-its-rise-fall-and-rise-again/

- Ford Capri – https://en.wikipedia.org/wiki/Ford_Capri

- Ford Capri development story – https://www.aronline.co.uk/cars/ford/capri/colt-development-story/

- https://www.crowood.com/products/british-ford-cars-of-the-1960s-and-1970s-by-james-taylor

- History of the Ford Capri: models, specs and the controversial 2024 return – https://www.autoexpress.co.uk/ford/capri/105874/history-ford-capri-models-specs-and-controversial-2024-return