Introduction

In the bustling streets of post-war Hull, the sight of crumpled cars and mangled metal was all too common. The scars of road accidents marred the beauty of many a motor vehicle, leaving them to be deemed irreparable by most. However, in a small workshop on Arthur Street, miracles were being performed daily. This is the story of how one seemingly irreparable Opel was brought back to life, thanks to the skill and dedication of a master craftsman and the cutting-edge products of Suffolk Iron Foundry (SIF).

The Challenge

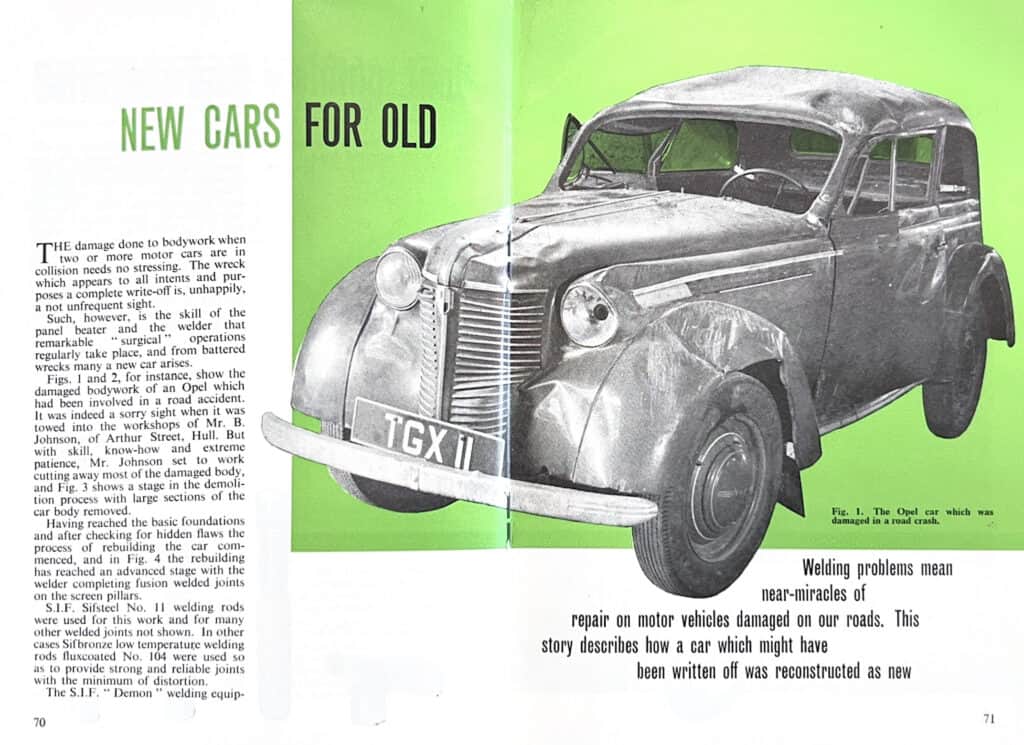

The Opel in question had been involved in a severe collision, resulting in extensive damage to its bodywork. When it was towed into the workshop of Mr. B. Johnson, it appeared to be a hopeless case—a complete write-off. The vehicle’s crumpled frame, twisted panels, and shattered glass told a tale of destruction that few would dare to challenge.

The Artisan

Mr. B. Johnson, a seasoned panel beater and welder, was not one to shy away from such challenges. Known for his extreme patience, meticulous craftsmanship, and an almost surgical approach to car repairs, Johnson saw potential where others saw scrap. He set to work with a clear plan: to dismantle the damaged sections and rebuild the car from its very foundation.

The Process

- Assessment and Demolition:

- Johnson began by carefully cutting away the irreparably damaged parts of the Opel. Figures 1 and 2 in the documentation showcase the extent of the initial damage. This phase was akin to a surgeon removing damaged tissue before a transplant.

- Stripping Down to Basics:

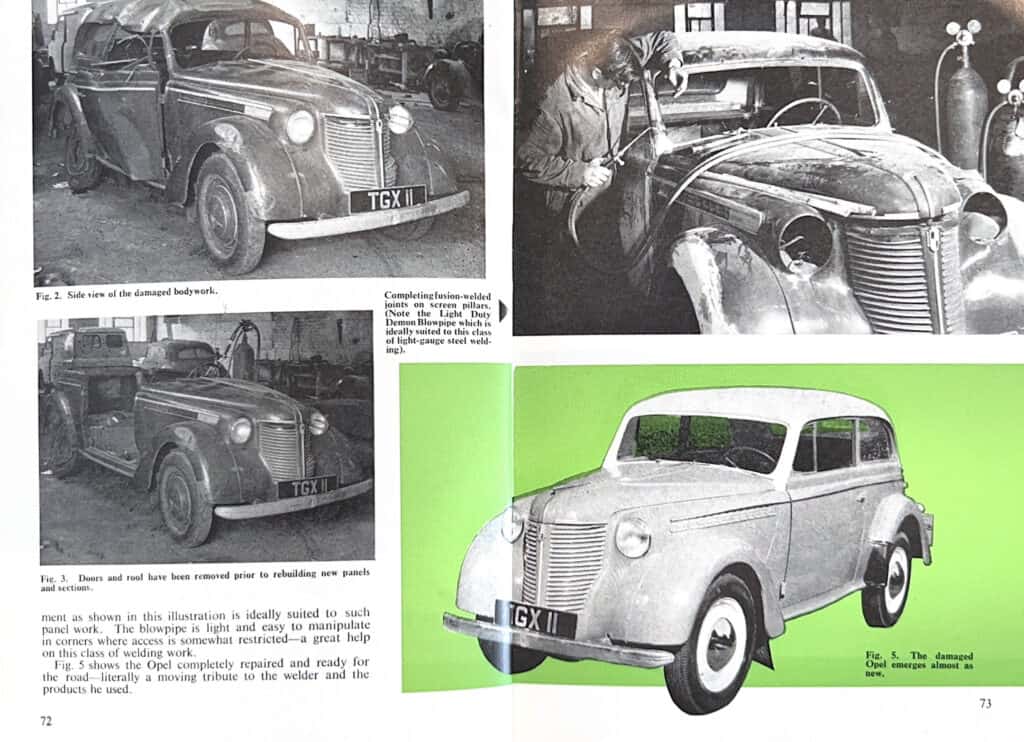

- As seen in Figure 3, Johnson removed the doors and roof, preparing the vehicle for the installation of new panels and sections. This meticulous process was crucial for ensuring that no hidden flaws would compromise the integrity of the repair.

- Reconstruction and Welding:

- With the basic foundations laid bare, the rebuilding process commenced. Johnson relied heavily on the advanced welding techniques facilitated by SIF’s products. Using S.I.F. Silfos No. 11 welding rods, he ensured that the joints were strong and reliable. The low-temperature Sirbonze flux-coated No. 104 rods were employed to minimize distortion, preserving the car’s original design.

- Fusion Welding Mastery:

- Figure 4 illustrates Johnson in the midst of completing fusion-welded joints on the screen pillars. The Light Duty Demon Blowpipe from SIF, ideally suited for light-gauge steel welding, played a pivotal role in this phase. Its light and easy-to-manipulate design allowed Johnson to work in tight corners with precision, a testament to SIF’s innovation in welding technology.

The Result

After weeks of painstaking labor, the Opel emerged almost as new (Figure 5). The transformation was nothing short of miraculous. What was once a mangled wreck now stood ready for the road, a moving tribute to the combined prowess of a master craftsman and the cutting-edge tools provided by SIF.

Conclusion

This case study is not just about the remarkable revival of a wrecked car; it is a celebration of skill, innovation, and perseverance. Mr. B. Johnson’s ability to see beyond the damage and his unwavering dedication to his craft were crucial. However, it was the support from Suffolk Iron Foundry, with their state-of-the-art welding products, that made such a transformation possible.

In the annals of automotive repair, stories like this stand as a testament to what can be achieved when human ingenuity meets technological excellence. The Opel’s resurrection is a shining example of how old wrecks can indeed become new wonders, inspiring generations of craftsmen and engineers alike.

- References –

- opel 1940 olympia – https://classiccarcatalogue.com/OPEL_1940.html

- Article Links –