Introduction

In the heart of the 20th century, the industrial landscape was rapidly evolving. The production of industrial gases became a cornerstone of modern industry, enabling countless processes and innovations. One company at the forefront of this revolution was Air Products Ltd., a specialist in producing large quantities of gases and fabricating the intricate plants required for their production. Central to their success was the precision and reliability of their welding techniques, an area where the expertise and products of Suffolk Iron Foundry (SIF) played a crucial role.

The Industrial Challenge

Air Products Ltd. faced a formidable challenge: the production and storage of industrial gases such as oxygen, nitrogen, and argon required plants with exceptional design and fabrication standards. The slightest imperfection in welding could lead to catastrophic failures, especially given the extreme conditions under which these gases were produced and stored. Leaking liquid oxygen, for instance, could ignite upon contact with oil, underscoring the need for flawless welding.

The Role of Welding in Gas Production

The process of producing these gases involves reducing air to extremely low temperatures until it liquefies, followed by the separation of its components through fractional distillation. This method required equipment that could withstand the harshest conditions, where temperatures plummeted to -196 degrees Celsius. The entire operation depended on the integrity of the welds that held the equipment together.

Air Products Ltd.: A Pioneer in Precision

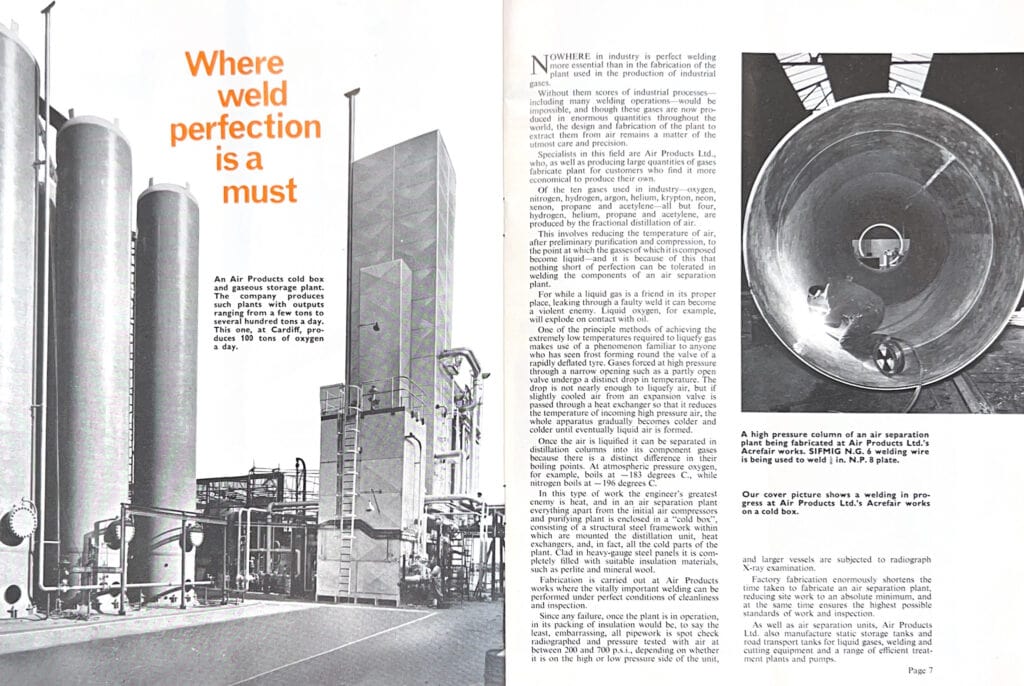

Air Products Ltd. had established itself as a pioneer in this field, designing and fabricating plants with outputs ranging from a few tons to several hundred tons a day. Their plant in Cardiff, capable of producing 100 tons of oxygen daily, stood as a testament to their expertise. The company’s cold boxes and gaseous storage plants were marvels of engineering, requiring the highest standards of welding to ensure safety and efficiency.

The Crucial Support from Suffolk Iron Foundry

Enter Suffolk Iron Foundry (SIF), a name synonymous with excellence in welding products. The use of SIFIMG N.G.6 welding wire at Air Products Ltd.’s Acrefair works was a game-changer. This welding wire, known for its reliability and superior performance, ensured that every weld was perfect. The precision and quality of SIF’s products were critical in fabricating the high-pressure columns and other components of the air separation plants.

Historical Significance: The Air Separation Plant

One notable project was the fabrication of a high-pressure column for an air separation plant. This plant, which required meticulous attention to detail, involved welding inch-thick N.P. 8 plates. The success of this endeavor was not just a technical achievement but a historical milestone in industrial gas production. The use of SIF’s welding wire ensured that the column could withstand the extreme pressures and temperatures, maintaining the integrity of the entire system.

Rigorous Testing and Quality Assurance

The commitment to quality didn’t stop at welding. Air Products Ltd. implemented rigorous testing protocols to ensure the safety and reliability of their plants. Welds were radiographed, and pressure tests were conducted at between 200 and 700 p.s.i., depending on whether the unit was on the high or low-pressure side. Larger vessels underwent radiographic X-ray examinations, further ensuring that no defects were present.

Factory Fabrication: A Model of Efficiency

Factory fabrication at Air Products Ltd. significantly shortened the time required to produce air separation plants. This efficiency translated into cost savings for customers while maintaining the highest possible standards of work and inspection. The integration of SIF’s welding products into this process exemplified how collaboration between companies could lead to groundbreaking advancements in industrial technology.

Conclusion

The partnership between Air Products Ltd. and Suffolk Iron Foundry stands as a shining example of industrial innovation and excellence. The story of how SIF’s welding products supported the creation of state-of-the-art gas production plants highlights the importance of precision and quality in engineering. This historical case study not only celebrates the achievements of these companies but also underscores the critical role of welding in shaping the modern industrial landscape.

Through the meticulous efforts of Air Products Ltd. and the superior welding solutions provided by SIF, the production of industrial gases was revolutionized, paving the way for future advancements and ensuring the safety and efficiency of countless industrial processes.