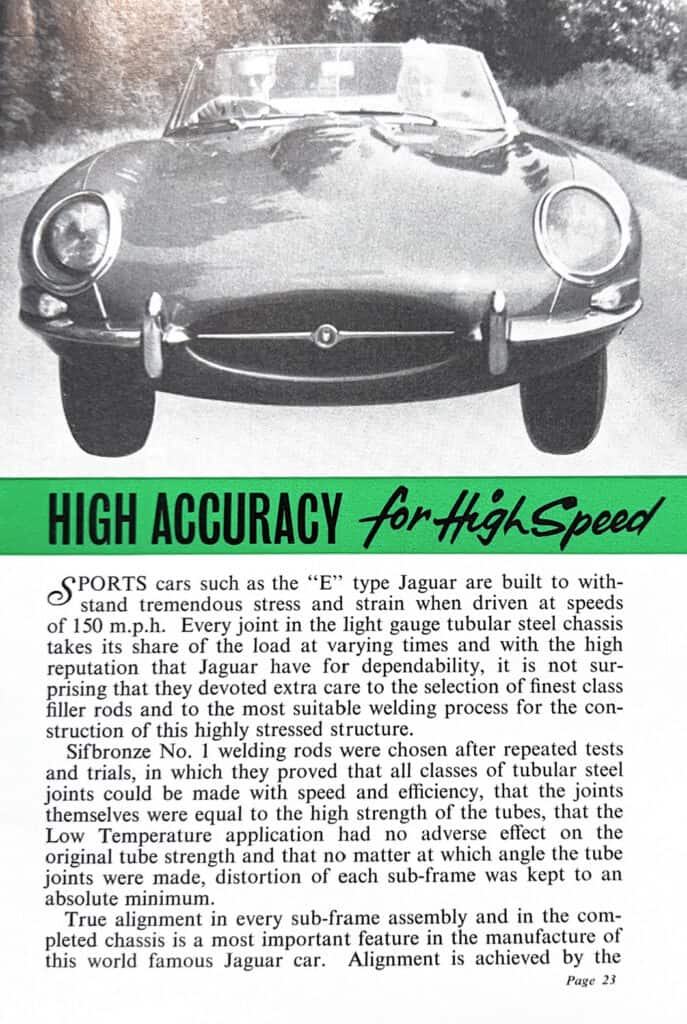

The iconic Jaguar E-Type, renowned for its sleek design and ability to reach speeds of 150 mph, required advanced engineering solutions to meet the demands of high-speed motoring. Central to the construction of this legendary sports car was its light gauge tubular steel chassis, which needed to endure tremendous stress while maintaining alignment and integrity under extreme conditions. Jaguar turned to specialized welding techniques to ensure the strength and precision of every joint in this high-stress structure, and Sifbronze products were at the heart of this solution.

Products Used in Jaguar E-Type Construction:

- Sifbronze No. 1 Welding Rods: These rods were used to join tubular steel chassis components. After extensive tests and trials, Sifbronze No. 1 proved to be the optimal choice for maintaining the high strength required at each joint without compromising the original tube strength.

- Sifsteel No. 11 Filler Wires: Essential for precision welding of the smaller, intricate parts of the chassis, these filler wires ensured that all joints were reliably fused, contributing to the overall structural integrity of the vehicle.

- Low-Temperature Brazing Techniques: By employing low-temperature brazing methods, Jaguar’s engineers minimized the risk of heat distortion, ensuring that each subframe remained true to its alignment. This was crucial in preserving the lightweight yet strong framework needed for the car’s high-speed performance.

The use of Sifbronze No. 1 welding rods was instrumental in the construction of the Jaguar E-Type. These rods were specifically chosen because they not only matched the strength of the tubular steel chassis but also allowed for clean, efficient welds that prevented distortion. The low-temperature application of these rods further ensured that the original strength of the tubes remained intact, preserving the car’s structural integrity.

Additionally, the precision of Sifsteel No. 11 filler wires played a crucial role in welding the more intricate components, allowing Jaguar to achieve high-quality joints with minimal heat input and thus avoid any warping or misalignment of parts. This attention to detail was critical in ensuring that every subframe was assembled with precision, maintaining the car’s high-performance standards.

The result was a sports car that looked stunning and could withstand the rigours of high-speed driving, with every weld and joint contributing to the vehicle’s exceptional durability and reliability. Thanks to Sifbronze’s products, Jaguar could deliver on its promise of speed, strength, and elegance, making the E-Type one of the most iconic cars in automotive history.

- References –

- Jaguar E-type | 60th Anniversary – https://www.youtube.com/watch?v=wMERFZZH7B4

- Jaguar E-Type logo and vent – https://www.flickr.com/photos/cdevers/3293246252

- New “E” Type Jaguar (1961) – https://www.youtube.com/watch?v=ib5w4pnwV1E

- Article Links –

- The History of Jaguar E-Type Racing – https://etypeuk.com/newsroom/articles/the-history-of-jaguar-e-type-racing/

- E-Type Reborn – https://www.jaguar.co.uk/about-jaguar/jaguar-classic/e-type-reborn.html

- Tested: 1961 Jaguar E-type Proves Every Bit as Great as It Looks

- Tested: 1961 Jaguar E-type Proves Every Bit as Great as It Looks

- Tested: 1961 Jaguar E-type Proves Every Bit as Great as It Looks

- Tested: 1961 Jaguar E-Type Proves Every Bit as Great as it Looks – https://www.caranddriver.com/reviews/a15112090/1961-jaguar-e-type-road-test-review/

- History of E-Type – https://etypeuk.com/newsroom/history/