Products Used in GRD Racing Car Manufacturing:

- Sifbronze No. 2 Nickel/Bronze Rods: Integral to the construction of GRD’s high-performance racing car chassis, providing strength and flexibility for the demands of Formula Two racing.

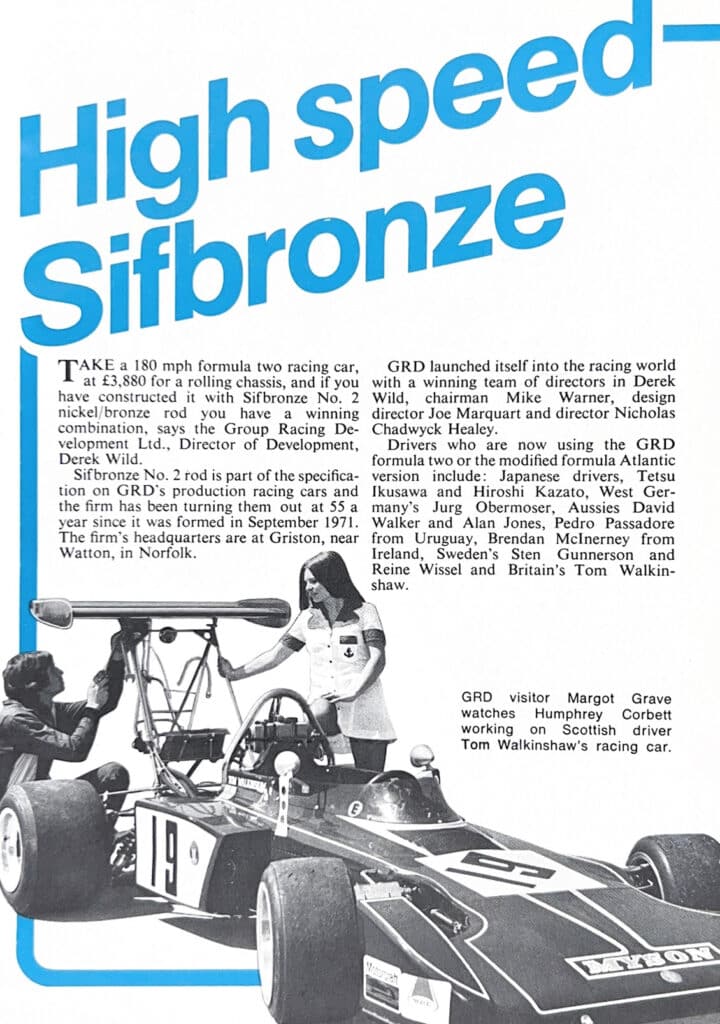

In the world of high-speed motorsport, every component of a racing car must perform flawlessly under extreme conditions. GRD (Group Racing Development) burst onto the scene in 1971, quickly establishing itself as a competitive force in Formula Two and other racing formats. Behind the success of their 180 mph racing cars was a combination of innovative engineering, strategic design, and high-performance materials like Sifbronze No. 2 rods.

Derek Wild, the Director of Development at GRD, noted that using Sifbronze was not just a choice but a specification in their production cars. With their nickel/bronze composition, these brazing rods allowed the GRD team to create a lightweight yet durable chassis to withstand the intense forces experienced on the track.

The Role of Sifbronze No. 2 in GRD Racing Cars

A Formula Two car’s chassis must be solid and flexible, capable of handling high-speed cornering, braking, and acceleration. The Sifbronze No. 2 rods were ideal for this purpose. Their low-temperature brazing properties made them perfect for joining different frame sections without compromising the materials’ structural integrity.

Sifbronze provided high tensile strength and the ability to resist corrosion and fatigue—essential qualities for a racing car expected to endure long races at high speeds. In particular, the nickel content in the Sifbronze No. 2 rods ensured that the joints maintained their strength and resilience even under the punishing conditions of Formula Two racing.

GRD’s Rise to Success

GRD positioned itself as a leader in racing car innovation since its inception. Formed in September 1971, the company quickly gained a reputation for producing competitive and reliable cars, turning out 55 vehicles in its first year alone. Based in Griston, Norfolk, the GRD team relied on a combination of experienced engineers and skilled craftsmen supported by the best materials available—like Sifbronze.

By incorporating Sifbronze No. 2 rods into their production process, GRD could construct a rolling chassis for £3,880—a competitive price at the time that still allowed for high performance. The brazing process allowed GRD to maintain the car’s structural integrity while keeping the weight to a minimum, a key factor in achieving the car’s impressive 180 mph speeds.

International Success and Top Drivers

GRD’s racing cars quickly found favour with drivers from all over the world. The company’s success was bolstered by the talent behind the wheel, with renowned drivers like Tetsu Ikusawa, Hiroshi Kazato, David Walker, and Alan Jones all piloting GRD machines to victory.

As GRD expanded into Formula Atlantic, a modified version of Formula Two, their cars remained competitive internationally. Whether racing in Japan, Europe, or South America, GRD vehicles consistently proved their worth, with the reliability of Sifbronze construction playing a key role.

High-Speed Performance Meets Precision Engineering

Every component in a Formula Two car must be carefully considered, and the precision offered by Sifbronze No. 2 rods allowed GRD to build vehicles that could handle the tight turns and high-speed straights of circuits like Silverstone and Hockenheim. The nickel/bronze rods enabled precise, high-quality brazing at critical points in the chassis, ensuring that each car could handle the unique challenges of Formula Two racing.

As GRD expanded its operations, the team continued to push the boundaries of what was possible in racing car design. With Sifbronze products forming the backbone of their construction process, GRD created cars that were not only fast and agile but also durable and reliable—a combination that led to numerous victories and podium finishes.

A Legacy of Innovation

The partnership between Sifbronze and GRD exemplifies how the right materials can elevate a design from good to great. Using Sifbronze No. 2 rods, GRD created high-performance racing cars that could compete at the highest levels of motorsport. The durability and strength provided by Sifbronze ensured that GRD cars remained competitive, race after race, helping the company build a legacy in motorsport.

Today, the impact of Sifbronze in motorsport can still be felt. The materials and techniques developed for use in Formula Two racing have influenced the construction of modern racing cars, demonstrating the lasting importance of precision brazing and welding in high-performance engineering. Through their collaboration, GRD and Sifbronze helped push the limits of speed and endurance, leaving a lasting mark on the history of Formula Two racing.