Introduction

In the early 20th century, the maritime industry faced significant challenges in material durability, strength, and maintenance costs. Traditional materials like wood and steel, while effective, were prone to issues such as rot, corrosion, and high upkeep. This case study explores how the advent of aluminium, particularly with the support of Suffolk Iron Foundry (SIF), revolutionized boat building, marking a pivotal shift in maritime engineering.

Historical Context and the Advent of Aluminium

Aluminium first entered the boat construction scene as early as 1891, thanks to an enterprising Swiss firm that built the first aluminium boat. However, it wasn’t until the 1920s that aluminium truly began to establish itself as a game-changer in the maritime industry. This shift was significantly bolstered by the development of aluminium-magnesium alloys in 1929, which addressed early issues of strength and marine corrosion.

The Role of Suffolk Iron Foundry (SIF)

Founded in 1925, Suffolk Iron Foundry (SIF) quickly became a critical player in the advancement of aluminium technology. While SIF’s primary business focused on producing high-quality cast iron and later branching into various metalworking and manufacturing domains, their expertise in metallurgy played a crucial role in supporting companies that were pioneering the use of aluminium in marine applications.

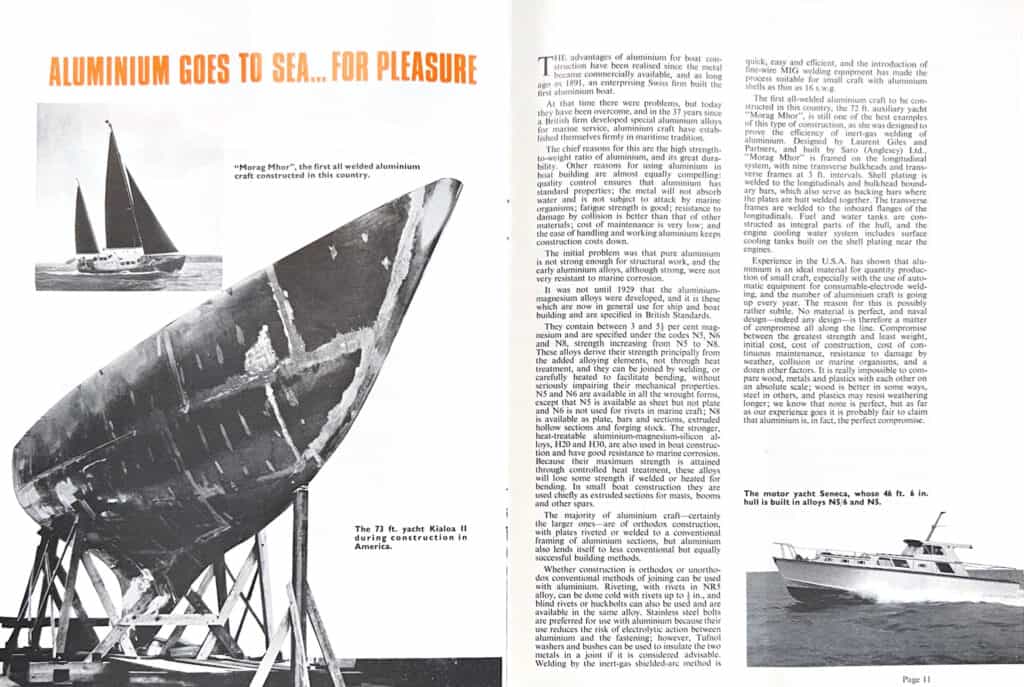

Case Example: The 73 ft. Yacht Kialoa II

One notable example of aluminium’s successful application in boat building is the construction of the 73 ft. yacht Kialoa II in America. During the early stages of this project, SIF’s metallurgical expertise was sought to refine the aluminium-magnesium alloy compositions, ensuring they met the specific strength and durability requirements for marine use.

Kialoa II’s construction highlighted several key advantages of aluminium:

- High Strength-to-Weight Ratio: Enabled a lighter, faster vessel without compromising on strength.

- Durability and Low Maintenance: Reduced maintenance costs and prolonged the yacht’s operational life by resisting marine corrosion and damage from marine organisms.

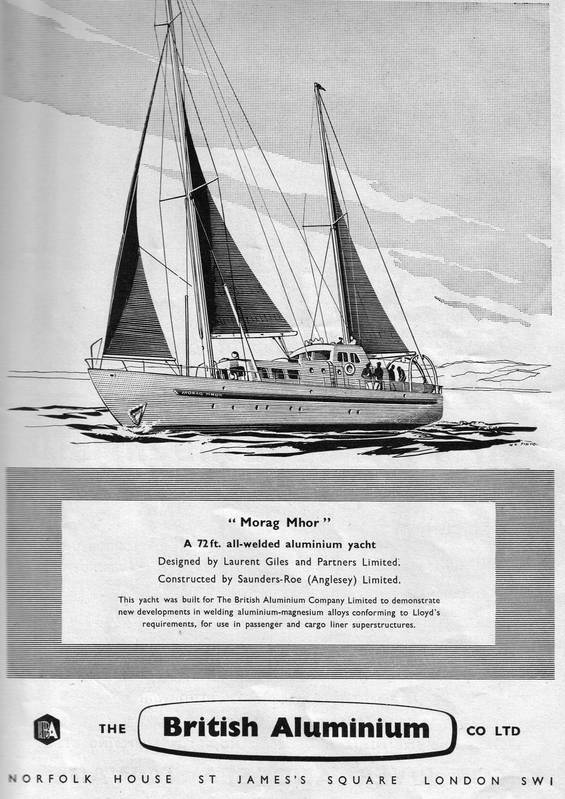

The Innovation of “Morag Mhor”

“Morag Mhor,” the first all-welded aluminium craft constructed in the country, stands as a testament to the transformative impact of aluminium. Designed by Laurent Giles and Partners and built by Saro (Anglesey) Ltd., this 72 ft. auxiliary yacht showcased the potential of aluminium in crafting durable, efficient maritime vessels.

SIF’s contribution to “Morag Mhor” was primarily through their innovative welding techniques and alloy formulations. The company’s extensive research and development in metal joining methods, particularly in the inert-gas shielded-arc welding, provided the necessary technology to ensure the structural integrity and longevity of aluminium vessels.

Aluminium Alloys: The Backbone of Modern Boat Building

The development and refinement of aluminium alloys, particularly those containing 3-5% magnesium (codes N5, N6, N8), were crucial in overcoming early challenges. These alloys, specified in British Standards, derived their strength from added elements rather than heat treatment, allowing them to be welded and shaped without losing mechanical properties.

SIF’s ongoing research in alloy compositions and their properties ensured that these materials met the rigorous demands of maritime applications. By providing high-quality materials and technical support, SIF enabled shipbuilders to construct vessels that were not only strong and durable but also easier and more cost-effective to maintain.

Conclusion

The story of aluminium’s rise in boat building is a testament to the power of innovation and collaboration. Through the efforts of pioneering companies and the crucial support of metallurgical experts like Suffolk Iron Foundry, the maritime industry was able to embrace aluminium as a superior material. This transition not only improved the performance and longevity of vessels but also set new standards in marine engineering.

As we reflect on the historical journey of aluminium in the maritime sector, it is clear that the contributions of SIF and other industry leaders were instrumental in shaping a future where boats could be lighter, stronger, and more resilient, paving the way for the modern era of boat building.

- References –

- Morag Mhor Poster – https://www.shipsnostalgia.com/media/morag-mhor.132902/

- Morag Mhor at Sea – https://www.shipsnostalgia.com/media/wishbone.151187/