Introduction

The 1960s heralded a new era in boat building, with aluminium emerging as the material of choice for innovative shipbuilders. This case study explores how John Perry (Marine) Ltd., a forward-thinking company based in Strood, Kent, leveraged aluminium to construct the first motor yacht of its kind. With crucial support from Suffolk Iron Foundry (SIF), founded in 1925, this venture showcases the synergy between innovation and expertise.

John Perry (Marine) Ltd.: Pioneering Aluminium Boats

John Perry (Marine) Ltd. had a vision: to revolutionize the boat-building industry using aluminium. The company set out to build a motor yacht for an American customer, marking a significant departure from traditional materials like steel. The yacht, designed to be the fastest of its kind and to receive a 100A classification by Lloyds, would embody the latest in marine engineering and luxury.

Suffolk Iron Foundry’s Essential Contribution

While Suffolk Iron Foundry (SIF) was renowned for its high-quality cast iron and metalworking solutions, its expertise in aluminium welding materials was pivotal for this project. SIF supplied the SIFMIG NG 6 aluminium filler wire, ensuring that the yacht’s construction met the highest standards of durability and performance.

Building the Future: The Aluminium Motor Yacht

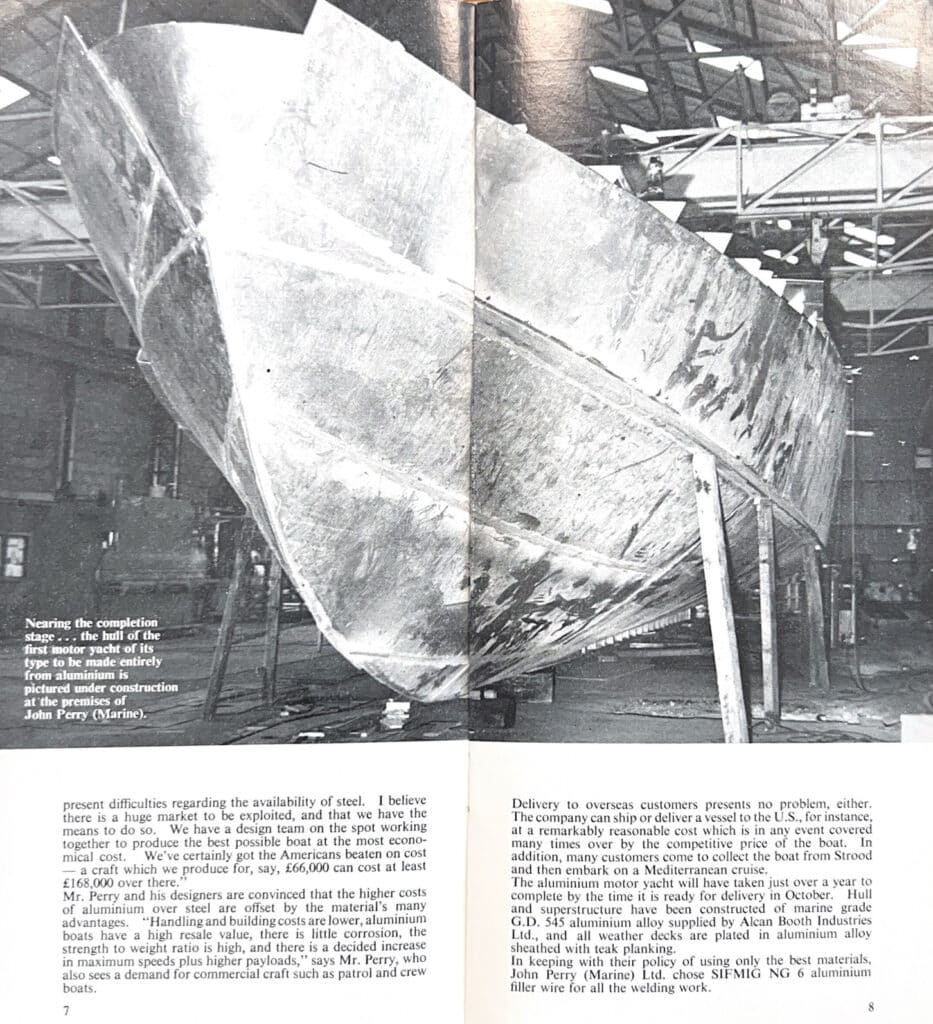

The motor yacht under construction by John Perry (Marine) Ltd. featured state-of-the-art design and engineering:

- Performance: Equipped with twin Mercedes engines of 1,000/1,350 b.h.p. each, the yacht was capable of achieving speeds between 18-26 knots, depending on displacement.

- Luxury: The yacht included a large owner’s stateroom, three double guest staterooms with bathrooms, a total of eight guest berths, air conditioning, hot and cold fresh water services, a modern galley, and provision for an Aston Martin.

The use of aluminium allowed for a design that was not only lightweight but also highly durable, providing a superior strength-to-weight ratio that enhanced both speed and payload capacity.

Advantages of Aluminium

John Perry and his team were convinced of the many benefits of aluminium over traditional materials:

- Cost Efficiency: Despite higher initial costs, aluminium’s lower handling and building expenses, coupled with its high resale value, offered significant savings.

- Corrosion Resistance: Aluminium’s natural resistance to corrosion drastically reduced maintenance needs.

- Performance: The strength-to-weight ratio of aluminium facilitated higher speeds and greater payloads, crucial for both commercial and luxury vessels.

John Perry proudly noted, “We’ve certainly got the Americans beaten on cost—a craft which we produce for, say, £66,000 can cost at least £168,000 over there.”

Market Expansion and Efficiency

The market potential for aluminium boats was clear, both domestically and internationally. John Perry (Marine) Ltd. could ship or deliver vessels to the U.S. at a competitive cost, further adding to their appeal. Many customers chose to collect their boats from Strood and embark on Mediterranean cruises, highlighting the practical and luxurious appeal of these yachts.

The aluminium motor yacht, completed in just over a year, demonstrated the efficiency and advantages of using aluminium. The hull and superstructure were crafted from marine-grade G.D. 545 aluminium alloy supplied by Alcan Booth Industries Ltd., with weather decks plated in aluminium alloy sheathed with teak planking.

Conclusion

The construction of the first all-aluminium motor yacht by John Perry (Marine) Ltd. represents a significant milestone in maritime engineering. Suffolk Iron Foundry’s support, through the provision of high-quality SIFMIG NG 6 aluminium filler wire, was crucial to this achievement. By embracing aluminium, John Perry (Marine) Ltd. set new standards for efficiency, performance, and luxury in boat building.

This case study illustrates the transformative power of innovation and the importance of collaboration between industry pioneers and expert suppliers. The success of John Perry (Marine) Ltd. and SIF in this venture continues to inspire and set benchmarks in the maritime industry, proving that the future of boat building is indeed bright with aluminium at its core.