Introduction

In the annals of industrial history, the advent of aluminium as a core manufacturing material marks a pivotal chapter. This lightweight yet robust metal revolutionized numerous industries, from transportation to maritime. At the heart of this transformation was Suffolk Iron Foundry (SIF), founded in 1925, whose innovative SIFMIG aluminium wires became instrumental in supporting various manufacturing processes. This case study explores how SIFMIG played a crucial role in advancing industries, especially during the challenging wartime period and in the post-war era.

The Challenge of Wartime Manufacturing

World War II imposed unprecedented demands on manufacturing industries. The need for durable, efficient, and versatile materials was paramount as countries mobilized for war. Aluminium, with its excellent strength-to-weight ratio and corrosion resistance, emerged as a vital resource. However, effective welding of aluminium posed significant challenges, requiring innovative solutions to ensure reliability and efficiency.

SIFMIG – The Game Changer

SIFMIG aluminium wires, developed by Suffolk Iron Foundry, offered a groundbreaking solution to these challenges. Designed to facilitate superior welding of aluminium, SIFMIG quickly gained acclaim for its reliability and performance.

- Road Tankers:

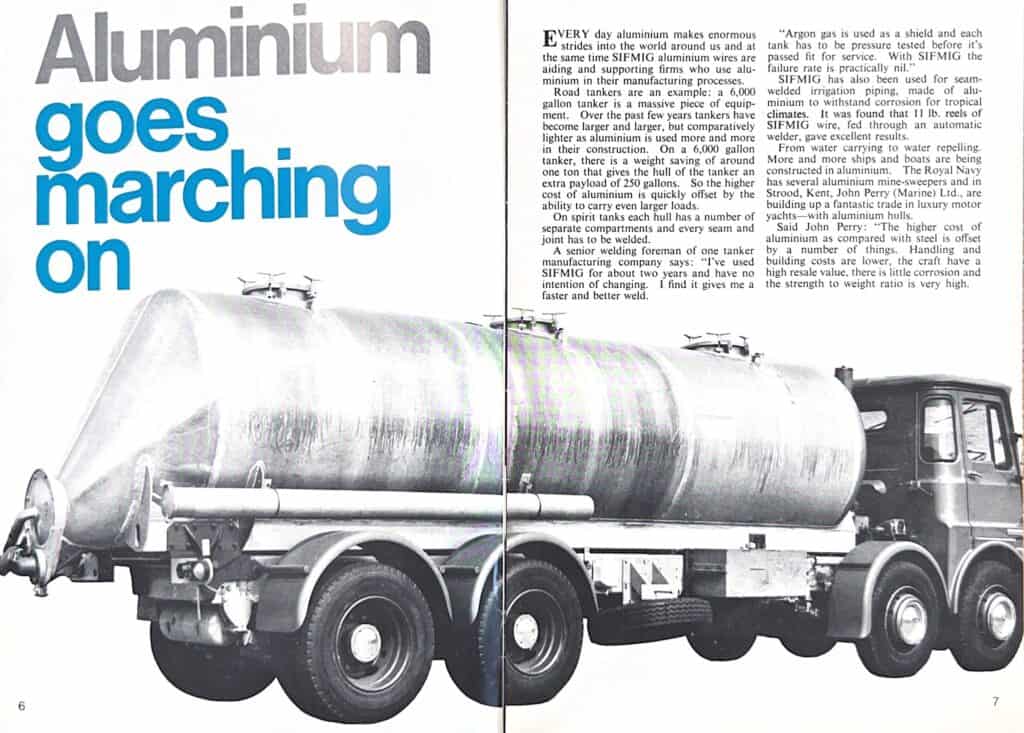

- A prime example of aluminium’s utility is in the construction of road tankers. A 6,000-gallon tanker, a critical asset for transporting fuel and supplies, benefited immensely from aluminium’s properties.

- The use of aluminium resulted in a weight saving of approximately one ton, allowing for an extra payload of 250 gallons. This weight efficiency not only enhanced operational capacity but also offset the higher cost of aluminium.

- Spirit Tanks:

- Spirit tanks, essential for transporting various liquids, featured hulls with multiple compartments. Each seam and joint required precise welding to ensure integrity.

- A senior welding foreman highlighted the exceptional performance of SIFMIG wires, noting their use over two years and emphasizing the faster and better welds achieved with SIFMIG.

SIFMIG in Diverse Applications

Beyond road tankers, SIFMIG aluminium wires proved invaluable across various applications, underscoring their versatility and effectiveness.

- Irrigation Piping:

- Seam-welded irrigation pipes made from aluminium needed to withstand tropical climates’ harsh conditions. SIFMIG wires facilitated the production of these pipes, providing excellent results when used with automatic welders.

- Maritime Innovations:

- The maritime industry, particularly during and after the war, saw significant advancements with aluminium. The Royal Navy’s mine-sweepers and luxury motor yachts by John Perry (Marine) Ltd. in Strood, Kent, leveraged aluminium for its superior properties.

- John Perry himself praised aluminium, stating that despite its higher initial cost compared to steel, the benefits included lower handling and building costs, high resale value, minimal corrosion, and a high strength-to-weight ratio.

Testimonials from the Field

The adoption of SIFMIG wires garnered positive feedback from industry professionals, reinforcing their impact:

- Senior Welding Foreman: “I’ve used SIFMIG for about two years and have no intention of changing. I find it gives me a faster and better weld.”

- John Perry: “The higher cost of aluminium as compared with steel is offset by a number of things. Handling and building costs are lower, the craft have a high resale value, there is little corrosion, and the strength to weight ratio is very high.”

These testimonials highlight the transformative role SIFMIG played in improving welding quality and manufacturing efficiency.

Historical Impact and Legacy

The introduction and widespread adoption of SIFMIG aluminium wires during World War II and in the subsequent rebuilding era were instrumental in advancing industrial capabilities. Suffolk Iron Foundry’s innovative approach not only addressed the immediate challenges of the time but also set a foundation for future technological progress.

Conclusion

This case study underscores the significant contributions of SIFMIG aluminium wires in transforming various industries during a critical period in history. By providing a reliable and efficient welding solution, Suffolk Iron Foundry enabled manufacturers to fully exploit the benefits of aluminium, resulting in lighter, stronger, and more durable products.

The legacy of SIFMIG continues to be felt today, reflecting Suffolk Iron Foundry’s commitment to quality and innovation. As industries evolve, the principles of ingenuity and excellence that defined SIFMIG’s impact remain central to ongoing advancements in manufacturing and material science. Through their pioneering efforts, Suffolk Iron Foundry has left an indelible mark on the fabric of industrial progress.

4o