Introduction

The mid-20th century saw British Railways grappling with the immense task of maintaining its extensive fleet of locomotives. Ensuring these powerful machines stayed operational was no small feat, and it required innovative solutions and reliable support. This case study explores how Suffolk Iron Foundry (SIF), founded in 1925, played a pivotal role in revolutionizing locomotive maintenance, particularly through the use of Sifbronze in welding repairs.

The Challenge of Locomotive Maintenance

British Railways’ locomotives were essential for the efficient movement of goods and passengers across the country. However, the constant wear and tear on these machines meant that regular maintenance and repairs were crucial. The reclamation departments of the British Transport Commission were tasked with this enormous responsibility, and they turned to innovative materials and techniques to keep the wheels turning.

Suffolk Iron Foundry’s Crucial Support

Suffolk Iron Foundry (SIF) had already made a name for itself in the metallurgical industry with its high-quality iron and metalworking products. In the 1950s and 60s, SIF introduced Sifbronze, a revolutionary material that quickly became indispensable for locomotive repairs. By supplying this crucial material, SIF enabled British Railways to make efficient, cost-effective repairs.

The Magic of Sifbronze

Sifbronze proved to be a game-changer for the maintenance teams. This versatile material was particularly well-suited for welding, which was essential for repairing worn and damaged locomotive parts. Its application resulted in significant savings by reducing the need for expensive new components.

Key Applications of Sifbronze:

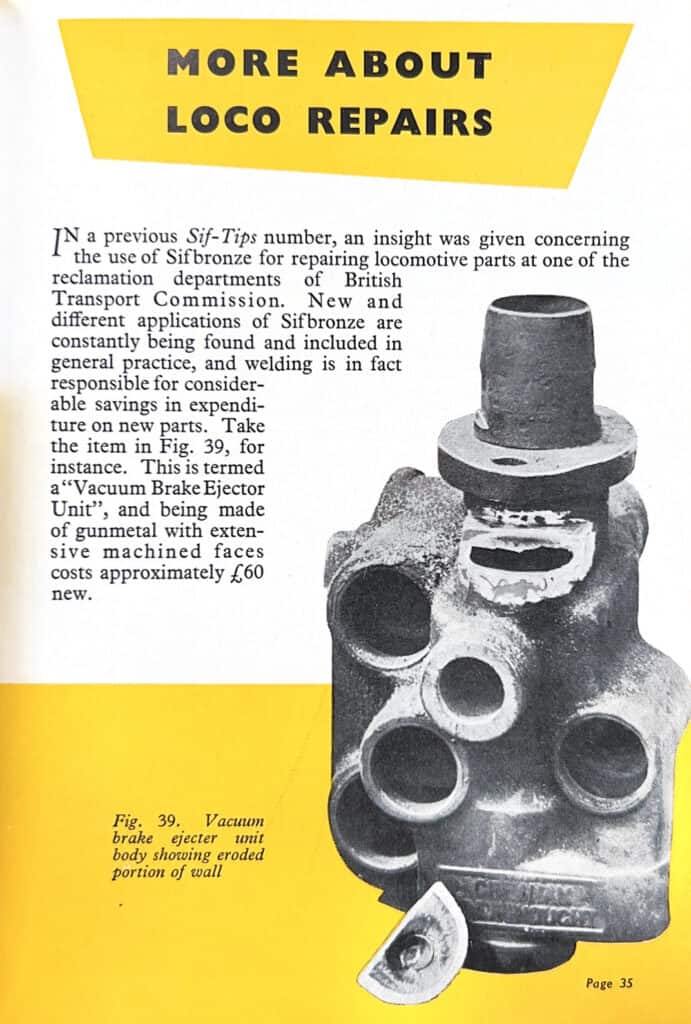

- Vacuum Brake Ejector Unit:

- Problem: The Vacuum Brake Ejector Unit, made of gunmetal, was prone to wear and damage due to its extensive use.

- Solution: Sifbronze welding allowed for the efficient repair of these units, restoring them to full functionality. This unit, costing around £60 new, could be effectively repaired, saving substantial costs.

Practical Implementation

The reclamation departments of British Railways, such as the one at Kentish Town, London, utilized Sifbronze extensively. Here’s a detailed look at how Sifbronze transformed their maintenance operations:

- Aluminium Repairs:

- Example: Repairing the “Scammell” radiator grille plate.

- Process:

- A specially designed jig was used to ensure precise alignment of broken pieces.

- Welding was performed using a General Duty Demon blowpipe and Sifalumin No. 15 filler metal, containing 5% silicon.

- Sifalumin No. 36 flux was used to manage oxides, and residual flux was removed within half an hour of welding to prevent defects.

- Outcome: The repaired grille plates were as good as new, maintaining the structural integrity and appearance of the locomotives.

- Cast Iron Repairs:

- Example: Repairing a cast iron exhaust manifold with a crack extending from the outer exhaust pipe flange into the manifold throat.

- Process:

- Local preheating prepared the cast iron for welding.

- The repair used S.I.F. “super-silicon” cast iron filler metal and “cast iron” flux, ensuring a sound, soft, and pore-free deposit.

- Outcome: The repaired exhaust manifolds functioned reliably, reducing downtime and extending the life of the components.

The Impact of SIF’s Support

SIF’s supply of Sifbronze and their technical expertise enabled British Railways to perform high-quality repairs on critical locomotive components. This support not only ensured the reliability and efficiency of the locomotives but also resulted in substantial cost savings by minimizing the need for new parts.

Conclusion

The collaboration between Suffolk Iron Foundry and British Railways exemplifies the power of innovation and quality materials in industrial maintenance. By introducing Sifbronze, SIF provided a solution that transformed locomotive maintenance, ensuring that British Railways could keep its fleet running smoothly and efficiently.

This case study highlights the importance of reliable support and innovative materials in overcoming maintenance challenges. The legacy of SIF’s contributions continues to inspire modern maintenance practices, reflecting a commitment to excellence that remains as relevant today as it was in the 20th century.