Introduction

The 1950s and 60s were a bustling era for British Railways, with an extensive network of rolling stock and motor vehicles requiring meticulous maintenance. The Materials Reclamation Department of the Road Motor Vehicles Section at Kentish Town, London, became a hub of engineering excellence. This case study delves into the critical role played by Suffolk Iron Foundry (SIF), founded in 1925, in supporting British Railways’ maintenance efforts, particularly through innovative gas welding techniques.

The Heart of Maintenance: Kentish Town

British Railways’ Kentish Town facility was a hive of activity, dedicated to the maintenance and repair of road vehicles essential for the efficient operation of the rail network. The team at Kentish Town, known for their expertise and precision, relied heavily on gas welding to repair key components made from aluminium, cast iron, and zinc base metals.

Suffolk Iron Foundry’s Crucial Support

Suffolk Iron Foundry (SIF) was already a well-established name in the metallurgical world, renowned for their high-quality materials and innovative solutions. For the team at Kentish Town, SIF supplied vital welding materials such as Sifalumin No. 15 and No. 36 flux, ensuring that each repair met the highest standards of durability and reliability.

Repairing Aluminium Components

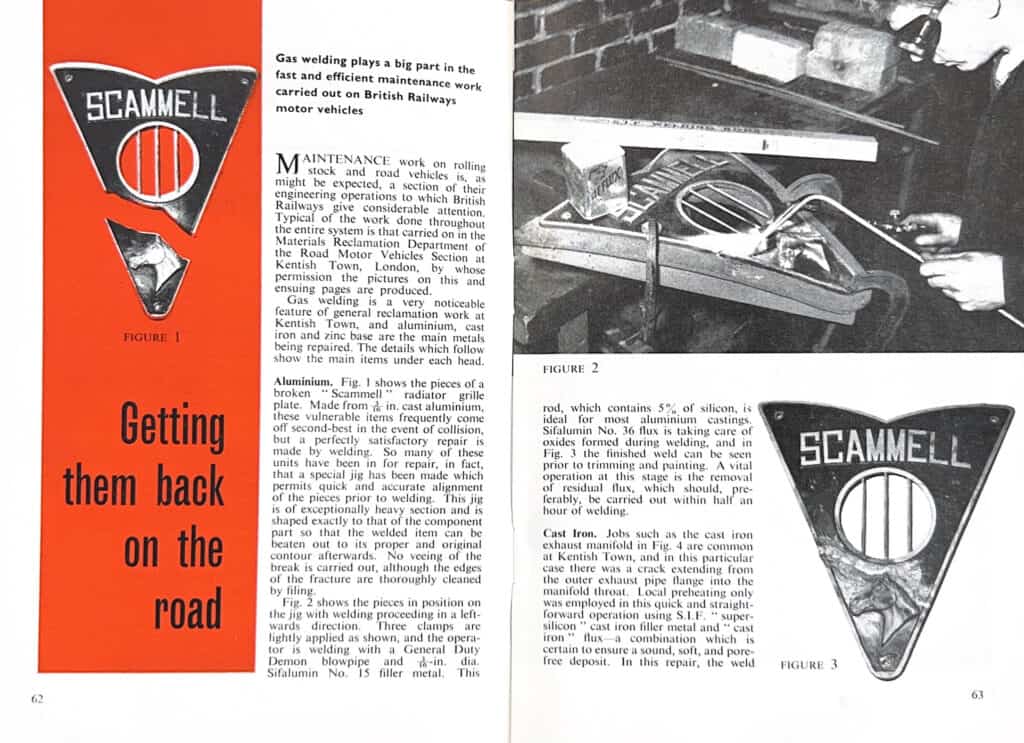

One of the common tasks at Kentish Town was repairing the “Scammell” radiator grille plates made from 5/16 in. cast aluminium. These components, often damaged in collisions, required precise welding to restore their functionality.

The Process:

- Preparation: The broken pieces were aligned using a specially designed heavy-duty jig that ensured accurate alignment.

- Welding: The operator used a General Duty Demon blowpipe and 5/16 in. dia. Sifalumin No. 15 filler metal, which contained 5% silicon. This combination was ideal for most aluminium castings.

- Finishing: Sifalumin No. 36 flux was used to manage oxides formed during welding. After welding, the removal of residual flux within half an hour was crucial to prevent any potential defects.

SIF’s high-quality filler metals and fluxes were essential in achieving reliable and robust repairs, enabling these vulnerable components to be quickly and efficiently restored.

Tackling Cast Iron Repairs

Another frequent challenge was repairing cast iron components, such as the exhaust manifold shown in Figure 4. This part had a crack extending from the outer exhaust pipe flange into the manifold throat.

The Process:

- Preheating: Local preheating was employed to prepare the cast iron for welding.

- Welding: The repair utilized S.I.F. “super-silicon” cast iron filler metal and “cast iron” flux. This combination ensured a sound, soft, and pore-free deposit, critical for the durability of the repaired component.

SIF’s specialized materials allowed the Kentish Town team to perform quick and straightforward repairs on cast iron parts, ensuring that vehicles were promptly back in service.

Ensuring Reliability and Efficiency

The meticulous maintenance work carried out at Kentish Town, supported by SIF’s high-quality materials, was instrumental in keeping British Railways’ motor vehicles operational. By focusing on precision and using the best available resources, the team ensured that each repaired component met stringent quality standards.

Conclusion

The collaboration between British Railways’ Kentish Town maintenance team and Suffolk Iron Foundry highlights the importance of quality materials and expert techniques in industrial maintenance. SIF’s contributions were crucial in enabling efficient and reliable repairs, ensuring that the wheels of British Railways kept turning smoothly.

This case study underscores the vital role of skilled craftsmanship and high-quality materials in maintaining essential transportation infrastructure. The legacy of this collaboration continues to inspire modern maintenance practices, reflecting a commitment to excellence and innovation that remains as relevant today as it was in the mid-20th century.

4o

- References –

- British Railways 1940 – 1950 – https://discover.hubpages.com/politics/Working-Class-life-in-the-1940s-and-1950s-Britain-Train-Travel

- King’s Cross Station (1950-1959) – https://www.youtube.com/watch?v=9Y9Xk_HRX-E

- King’s Cross Station Camden Town 1950’S – https://www.youtube.com/watch?v=Az7U2nGZ0VA

- Vintage LMS railway film – St Pancras Junction Relaying – 1947 – https://www.youtube.com/watch?v=plDBlQLt0EA

- British Railways Poster – https://www.alamy.com/stock-photo/1950s-british-railways-advertising.html?sortBy=relevant

- British Railways Double Royal Poster Advertising

- Recruitment Poster – https://www.gwra.co.uk/auctions/british-railways-recruitment-poster-good-job-for-y-2021dec-0583.html

- Article Links –

- British Railways – https://www.britannica.com/money/British-Railways

- History Timeline – https://railway200.co.uk/timeline/

- Railways in early nineteenth century Britain – https://www.parliament.uk/about/living-heritage/transformingsociety/transportcomms/roadsrail/kent-case-study/introduction/railways-in-early-nineteenth-century-britain/

- Our History – https://www.networkrail.co.uk/who-we-are/our-history/