Introduction

In the mid-20th century, the petrol and diesel pump industry was undergoing a period of rapid innovation. Companies were striving to design pumps that not only met functional requirements but also offered enhanced efficiency and reliability. Among these innovators was the manufacturer of the Beckmeter pump, a company that transformed the industry standard with its advanced features and robust design. Central to this transformation was the support from Suffolk Iron Foundry (SIF) and their pioneering Sifbronze welding techniques. This case study explores the historical development of the Beckmeter pump and the crucial role SIF played in its success.

The Challenge

Petrol and diesel pumps had evolved significantly from their utilitarian beginnings. However, with increasing demands for precision and efficiency, there was a need for pumps that could deliver fuel rapidly and accurately, all while maintaining robust performance in daily use. The Beckmeter pump aimed to meet these demands with its advanced design and built-in computer system for calculating fuel volume and cash value in one simultaneous action. Achieving this level of precision and reliability required not only innovative design but also impeccable manufacturing techniques.

The Role of SIF

Recognizing the technical challenges involved in manufacturing the Beckmeter pump, the company turned to Suffolk Iron Foundry (SIF). Established in 1935, SIF was renowned for its advanced welding technologies and commitment to quality. SIF’s Sifbronze welding technique was particularly suited for the precision required in the Beckmeter pump’s construction.

Sifbronze welding provided several advantages:

- Strength and Durability: Sifbronze welds were known for their exceptional strength and durability, ensuring that the Beckmeter pump could withstand constant daily use.

- Precision: The low application temperature of Sifbronze welding minimized the risk of distortion, allowing for precise assembly of the pump components.

- Versatility: Sifbronze was effective in welding different metals, crucial for tasks such as joining cast iron fittings to copper feed pipes, as required in the Beckmeter pump.

Engineering Excellence

The Beckmeter pump featured a number of advanced design elements, including a rapid automatic discharge rate and the ability to preset the pump to deliver a specific number of gallons. Once the preset quantity was reached, the pump would automatically stop, ensuring accurate fuel delivery. This level of precision was made possible by the meticulous manufacturing process, supported by SIF’s Sifbronze welding.

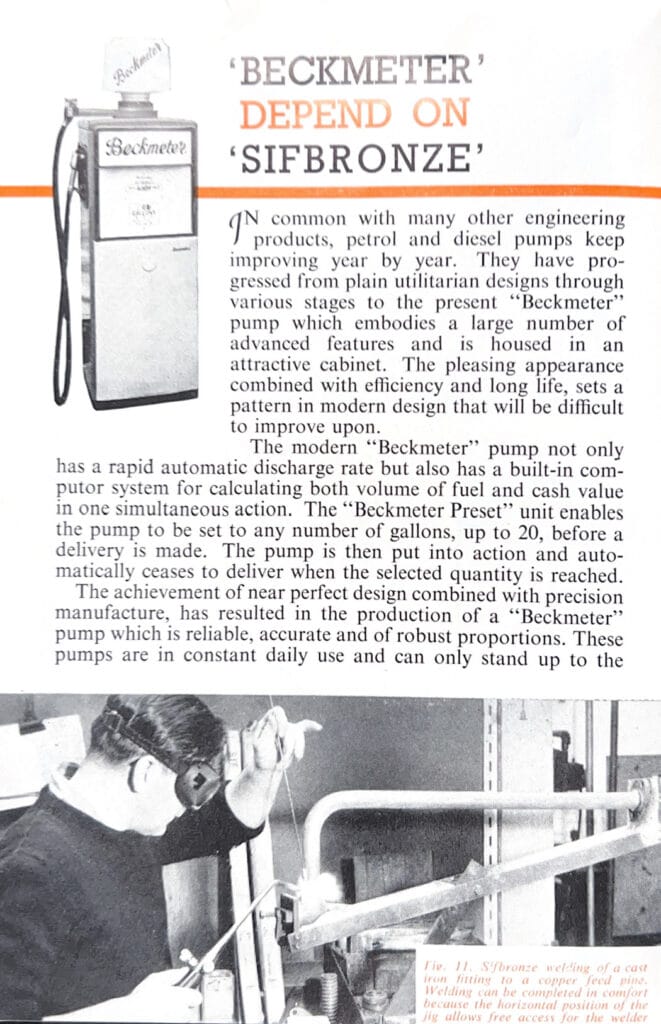

An example of SIF’s contribution can be seen in the welding of cast iron fittings to copper feed pipes. The horizontal positioning of the jig allowed welders to work comfortably and with high precision, ensuring strong and reliable joints. This attention to detail and commitment to quality was reflected in every aspect of the Beckmeter pump’s construction.

Impact and Legacy

The introduction of the Beckmeter pump set a new standard in the industry. Its combination of advanced features, reliable performance, and robust design made it a preferred choice for petrol stations and diesel service points. The pumps were praised for their efficiency and accuracy, reducing errors in fuel dispensing and enhancing customer satisfaction.

The role of SIF in this success cannot be overstated. Their Sifbronze welding technique provided the necessary precision and strength, ensuring that the Beckmeter pump could deliver on its promises of reliability and long life. This collaboration between the Beckmeter manufacturer and SIF exemplifies how innovative welding techniques can support and enhance industrial product development.

Conclusion

The Beckmeter pump revolutionized the petrol and diesel pump industry with its advanced features and robust design. Central to this achievement was the support from Suffolk Iron Foundry and their pioneering Sifbronze welding techniques. By providing precision, strength, and versatility, SIF helped ensure that the Beckmeter pump could meet the high demands of constant daily use.

This historical case study highlights the importance of innovation, meticulous manufacturing, and strategic partnerships in industrial product development. It showcases how the combination of advanced technology and skilled craftsmanship can lead to breakthroughs that redefine industry standards and leave a lasting legacy. The Beckmeter pump, supported by the expertise of SIF, remains a testament to the power of collaboration and technological excellence.

- References –

- Beskmeter Pump Ad – https://www.abebooks.co.uk/Beck-Company-Garage-Kerbside-Forecourt-Petrol/22446676400/bd