Introduction

In the heart of London’s Royal Docks, a renowned welding firm has been a cornerstone of the marine repair industry for nearly half a century. Known for their pioneering work in modern welding techniques, this firm employed up to 150 electric-arc welders at its peak, handling all kinds of marine repair work. As a testament to their expertise, they have long relied on the advanced materials and techniques developed by Suffolk Iron Foundry (SIF), founded in 1925. This case study explores how SIF’s innovations supported this welding firm in maintaining and repairing the vital infrastructure of the Royal Docks.

The Challenge

The firm faced numerous challenges in their work at the Royal Docks. Many of the repairs involved large cast iron components of ships, requiring meticulous and skilled welding. These components often needed full preheating, necessitating the construction of sizable firebrick furnaces fired by gas bunsens. The intense heat made close-up welding difficult and uncomfortable, posing significant challenges to the welders.

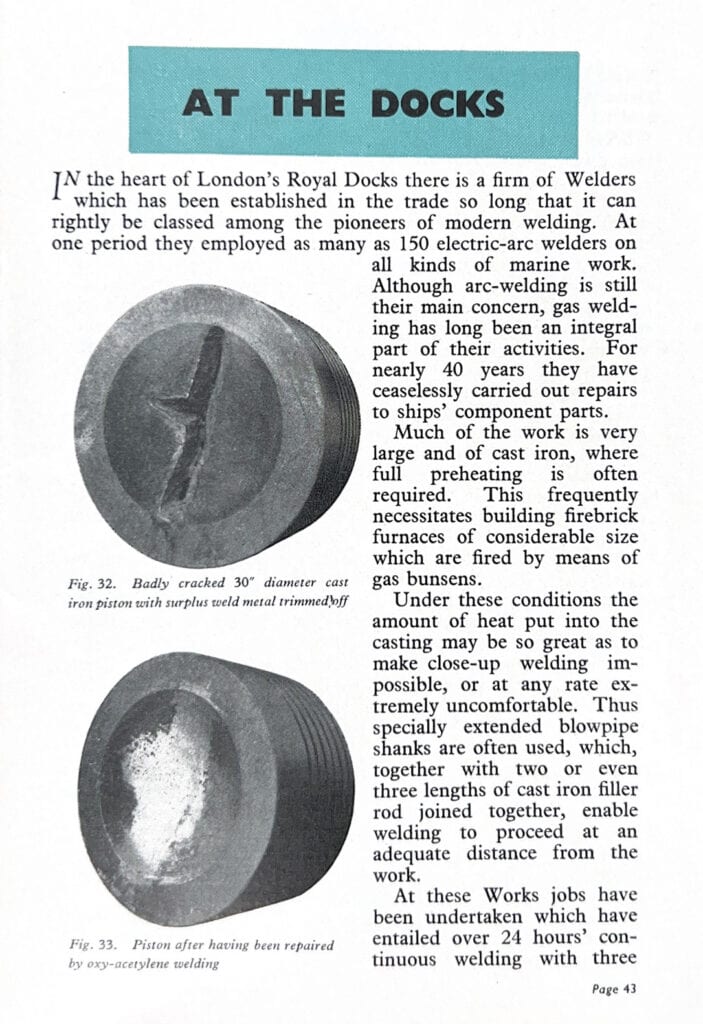

One particularly challenging job involved repairing a badly cracked 30-inch diameter cast iron piston. This kind of repair required not only advanced welding skills but also the right materials to ensure a durable and lasting fix.

The Role of Suffolk Iron Foundry (SIF)

Suffolk Iron Foundry (SIF), with its long history of innovation in welding technology, played a crucial role in supporting the welding firm at the Royal Docks. SIF’s expertise in producing high-quality welding materials, such as their cast iron filler rods, was instrumental in tackling the challenging repairs.

SIF’s cast iron filler rods, known for their excellent strength and reliability, were particularly suited for the demanding conditions of marine repair work. These rods enabled the welders to perform high-quality repairs on large cast iron components, even under extreme heat conditions.

Engineering Excellence

The repair of the 30-inch diameter cast iron piston is a prime example of the engineering excellence demonstrated by the welding firm, supported by SIF’s materials. The piston, badly cracked and in need of extensive welding, required careful preheating in a specially constructed firebrick furnace. To manage the intense heat, the welders used specially extended blowpipe shanks and multiple lengths of SIF’s cast iron filler rods, allowing them to work at a safe distance.

The welding process involved continuous welding over a span of more than 24 hours, with three welders working in shifts. This demanding job highlighted the firm’s dedication to quality and their reliance on SIF’s reliable welding materials.

The Outcome

Thanks to the superior quality of SIF’s cast iron filler rods and the welding firm’s expertise, the repair of the cast iron piston was successfully completed. The piston, once a broken and unusable component, was restored to its original strength and functionality, ready to be reinstalled in the ship.

This successful repair not only demonstrated the welding firm’s technical prowess but also underscored the vital role of high-quality materials in marine repair work. The collaboration between the welding firm and SIF ensured that even the most challenging repairs could be executed with precision and durability.

Legacy and Impact

The partnership between the welding firm at the Royal Docks and Suffolk Iron Foundry has left a lasting legacy in the marine repair industry. Their collaborative efforts have set a high standard for quality and reliability in welding repairs, ensuring the continued operation and safety of ships passing through the Royal Docks.

This historical case study highlights the importance of innovation, quality materials, and skilled craftsmanship in maintaining vital maritime infrastructure. Suffolk Iron Foundry’s contributions to the success of the welding firm’s operations at the Royal Docks exemplify how strategic support and advanced technology can overcome even the most daunting repair challenges.

In the ever-evolving world of marine engineering, the lessons learned from this collaboration continue to inspire and inform best practices, ensuring that the legacy of excellence in welding and repair work endures for future generations.

- References –

- London Docks 1950 – https://www.shipsnostalgia.com/media/london-docks-1950s.326299/

- Port Of London (1940-1949) – https://www.youtube.com/watch?v=FNfqz0Y3q2w

- Construction of the Royal Victoria Dock – https://www.layersoflondon.org/map/records/construction-of-the-royal-victoria-dock

- Flying the flag for the Royal Docks’ seafaring history – https://www.youtube.com/watch?v=D98WYr11NUU&t=1s

- Article Links –

- A history of the Royal Docks – https://www.royaldocks.london/articles/a-history-of-the-royal-docks

- Londons Royal Docks History – https://londonsroyaldocks.com/londons-royal-docks-history/