Introduction

The mid-20th century was a period of significant technological advancements in the maritime industry. Among the groundbreaking innovations was the use of aluminium in shipbuilding. This case study delves into the historical development of aluminium ships, spotlighting the construction of the Queen Elizabeth II (QE2) and illustrating how Suffolk Iron Foundry (SIF), founded in 1925, played a pivotal role in supporting this transformative movement.

The Advent of Aluminium in Shipbuilding

The journey of aluminium in shipbuilding began as early as 1891 with the construction of the first aluminium boat by a Swiss firm. However, it wasn’t until the late 1920s and early 1930s that aluminium alloys, specifically aluminium-magnesium alloys, were developed to withstand marine conditions. These alloys offered high strength-to-weight ratios and exceptional durability, making them ideal for maritime applications.

Queen Elizabeth II: A Revolution in Shipbuilding

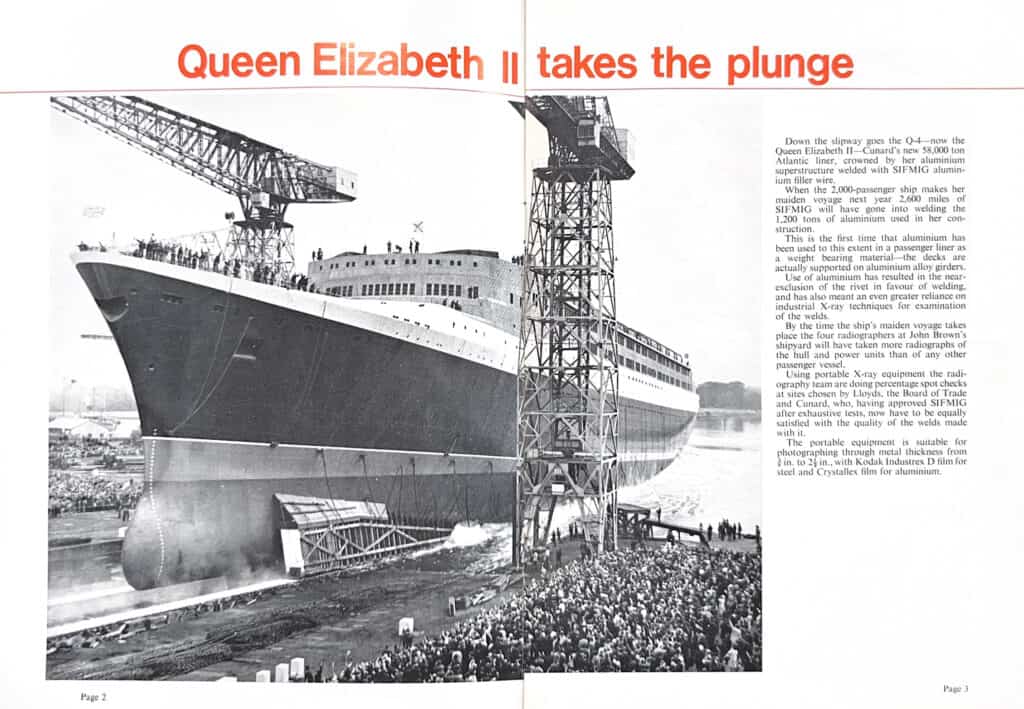

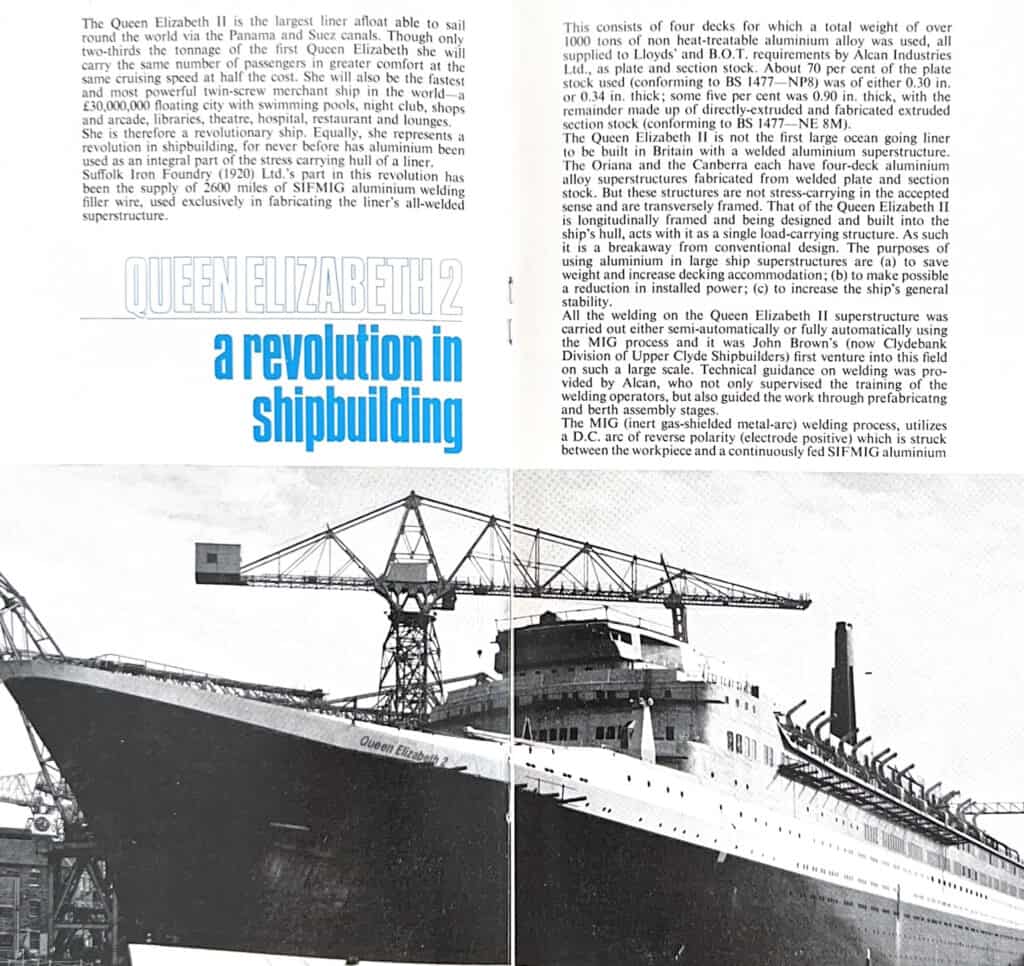

The Queen Elizabeth II, launched in the late 1960s, symbolized the pinnacle of aluminium application in shipbuilding. This 58,000-ton Atlantic liner, constructed by Cunard, incorporated 1,200 tons of aluminium in its superstructure. The QE2 was not just a marvel of engineering but also a floating city, boasting amenities such as swimming pools, night clubs, shops, libraries, theatres, hospitals, restaurants, and lounges.

Suffolk Iron Foundry’s Contribution

While Suffolk Iron Foundry’s primary focus was on high-quality cast iron and other metalworking solutions, their metallurgical expertise extended to supporting innovative projects like the QE2. SIF supplied 2,600 miles of SIFMIG aluminium filler wire, which was crucial for welding the ship’s aluminium components.

Aluminium’s Advantages in Maritime Construction

The use of aluminium in the QE2 brought several benefits:

- Weight Reduction and Strength: Aluminium’s high strength-to-weight ratio allowed for a lighter vessel without compromising structural integrity.

- Durability: Aluminium’s resistance to corrosion and marine organisms reduced maintenance costs and prolonged the ship’s lifespan.

- Welding Innovations: The shift from riveting to welding, facilitated by SIFMIG aluminium filler wire, enhanced the vessel’s structural strength and reliability.

Ensuring Quality: Radiographic Inspections

The construction of the QE2 also saw the extensive use of radiographic inspections to ensure weld quality. The radiography team at John Brown’s shipyard, equipped with portable X-ray machines, conducted percentage spot checks on the welds. These inspections were crucial for meeting the stringent quality standards set by Lloyds, the Board of Trade, and Cunard.

The Historical Impact of the QE2

The QE2’s successful use of aluminium demonstrated the material’s potential to revolutionize shipbuilding. It proved that aluminium could be used extensively in large-scale passenger liners, providing enhanced performance and reduced operational costs. This project set new benchmarks in maritime engineering, influencing future ship designs.

Conclusion

The story of the Queen Elizabeth II is a testament to the power of innovation and collaboration in the maritime industry. Suffolk Iron Foundry’s contribution, through the supply of SIFMIG aluminium filler wire and their metallurgical expertise, played a crucial role in realizing the potential of aluminium in shipbuilding. As we look back at this historical milestone, it is clear that the combined efforts of pioneering companies and expert suppliers like SIF have paved the way for modern advancements in maritime technology.

By embracing new materials and techniques, the maritime industry continues to evolve, building on the legacy of projects like the QE2. Suffolk Iron Foundry’s role in this journey exemplifies the importance of expertise and innovation in driving progress and achieving remarkable feats in engineering.

- References –

- QE2 – https://www.qe2.org.uk/

- QE2 Maiden Voyage (1969) – https://www.youtube.com/watch?v=wL70Lvl_Xrw

- Article Links –

- The Queen Elizabeth 2 – https://www.rmg.co.uk/stories/topics/queen-elizabeth-2-qe2

- A journey through time – https://www.qe2.com/en/history/

- https://www.britannica.com/topic/Queen-Elizabeth-British-passenger-ships

- QE2 History – https://www.chriscunard.com/qe2/qe2-history/