Introduction

In the bustling mid-20th century, the transportation industry was undergoing rapid advancements to meet the demands of post-war industrialization. Freight Bonallack, a visionary company known for its innovative transport solutions, faced the challenge of developing robust, reliable vehicles capable of handling heavy loads and specialized materials. Enter the Suffolk Iron Foundry (SIF), founded in 1925, whose expertise in welding technology provided the perfect synergy to drive forward Freight Bonallack’s ambitious projects.

The Challenge

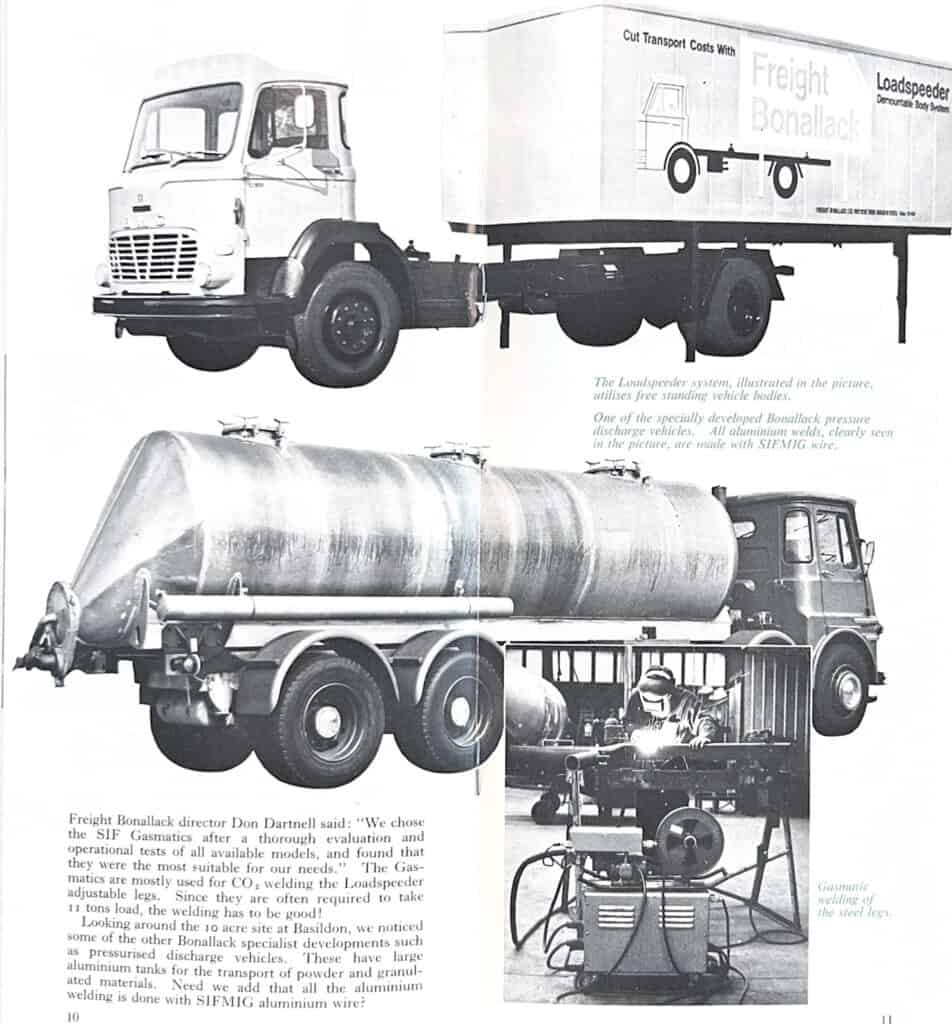

Freight Bonallack needed to cut transport costs and improve efficiency with a new line of vehicles. The Loadspeeder system was their brainchild—an advanced transportation solution that utilized free-standing vehicle bodies for versatile and cost-effective operations. However, this new system required high-quality, durable welds to ensure the safety and performance of the vehicles, especially given the heavy loads they were designed to carry.

The SIF Collaboration

Freight Bonallack turned to SIF for their renowned welding technology. After a thorough evaluation and operational tests of all available welding models, Freight Bonallack’s director, Don Dartnell, selected the SIF Gasmatics for their superior performance. The Gasmatics were particularly effective for CO₂ welding, a critical process for the Loadspeeder’s adjustable legs, which often needed to support up to 11 tons. The high standards of welding ensured the structural integrity and reliability of the vehicles under demanding conditions.

Implementation and Innovations

With SIF’s support, Freight Bonallack incorporated SIFMIG wire for all aluminum welding tasks. The SIFMIG wire proved indispensable in welding the aluminum components of the Loadspeeder system, as well as in other specialized vehicles like pressure discharge units. These units featured large aluminum tanks designed for transporting powdered and granulated materials, emphasizing the need for impeccable welding to prevent any leakage or structural failures.

The partnership extended to the no. 1 store site at Basildon, where SIF’s welding technologies were integral in developing a range of specialist vehicles. The seamless integration of SIFMIG aluminum wire and Gasmatics welding systems into Freight Bonallack’s manufacturing processes marked a significant milestone in vehicle production, enhancing both efficiency and safety.

Historical Impact

This collaboration was more than a mere business arrangement; it was a confluence of innovation and expertise that pushed the boundaries of transportation technology. Freight Bonallack’s Loadspeeder system, supported by SIF’s cutting-edge welding solutions, set new standards in the industry. The vehicles not only reduced transport costs but also provided a safer, more reliable means of transporting hazardous and heavy materials.

For SIF, founded in 1925 and already a stalwart in the welding industry, this partnership with Freight Bonallack highlighted their role as a critical enabler of industrial advancements. Their technologies were pivotal in overcoming the challenges faced by the transportation sector, ensuring that Freight Bonallack’s vehicles could meet and exceed the rigorous demands of the time.

Conclusion

The case of Freight Bonallack and SIF is a testament to the power of strategic partnerships in driving innovation. By combining Freight Bonallack’s vision for advanced transportation solutions with SIF’s unparalleled welding expertise, the two companies not only addressed immediate industry challenges but also set a foundation for future technological progress. This historical collaboration underscores the enduring impact of ingenuity and cooperation in shaping the industrial landscape.