Introduction

In the heart of London, an unexpected hero prowls the streets, devouring rubbish and refuse with voracious efficiency. This isn’t the typical predator of the deep but a mechanical marvel known as the “Shark.” Developed by Laird (Anglesey) Ltd., the Shark revolutionized refuse collection in the late 1960s, thanks in large part to the innovative support of the Suffolk Iron Foundry (SIF), founded in 1925. This case study delves into the historical partnership between these two engineering powerhouses and how they transformed waste management.

The Challenge

The 1960s saw a burgeoning need for efficient waste management solutions in rapidly growing urban centers. Local authorities struggled to cope with increasing volumes of refuse. Laird (Anglesey) Ltd., known for their expertise in manufacturing bridging equipment and other engineering marvels, recognized an opportunity. They aimed to create a vehicle that could not only collect but also compact and process waste on the go, thus maximizing efficiency and reducing trips to landfill sites.

The SIF Solution

To bring this vision to life, Laird turned to SIF, whose reputation for superior welding technology and materials made them the ideal partner. The Shark needed to be lightweight yet robust, capable of handling heavy loads without succumbing to wear and tear. SIF’s advanced welding techniques with aluminum and steel were crucial in achieving these goals.

Implementation and Innovations

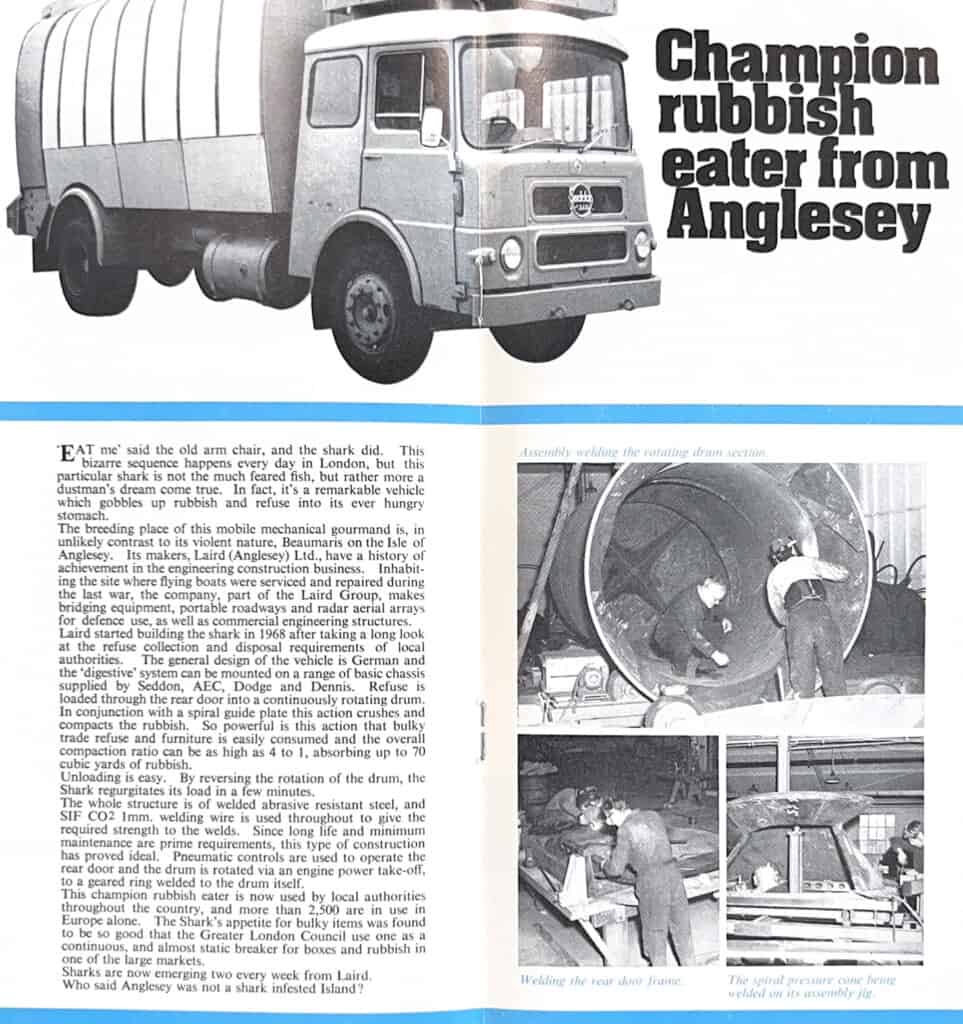

In 1968, after extensive research and development, Laird introduced the Shark. The vehicle’s design was a marvel of engineering. Refuse was loaded into a hopper, partially compacted by rotating vanes, and then funneled into a rotating drum via a spiral guide plate. This mechanism crushed and compacted the rubbish, achieving compression ratios as high as 4 to 1.

SIF’s role was pivotal in the construction of the Shark’s main components. The aluminum and steel elements of the vehicle were expertly welded using SIF’s state-of-the-art techniques. The aluminum provided the necessary lightness, ensuring that the vehicle could carry more waste per trip, while the steel components added the strength required to withstand the rigorous demands of daily operation. The use of SIFMIG aluminum wire and Sifalumin No. 14 filler rods ensured that the welds were both durable and resistant to corrosion.

Assembly and Testing

The assembly of the Shark was a meticulous process. Each rotating drum section was precision-welded, ensuring seamless integration with the vehicle’s overall structure. The spiral pressure cone, a key component in the compaction process, was welded on an assembly jig to guarantee exact alignment and functionality. The rear door frame, which needed to withstand significant pressure, was also reinforced with SIF’s superior welding techniques.

Before being deemed ready for service, each Shark underwent rigorous pressure testing to ensure that all seams and joints could withstand the operational stresses. This commitment to quality and durability was a testament to the engineering prowess of both Laird and SIF.

Historical Impact

The Shark quickly became a staple in refuse collection, with local authorities across Europe adopting the vehicle for its efficiency and reliability. Its ability to handle bulky items and large volumes of waste made it indispensable in urban waste management.

For SIF, the success of the Shark reinforced their position as leaders in welding technology. Their contributions to the project were not just in providing materials but in shaping the very backbone of the vehicle’s design. Founded in 1925, SIF’s legacy of innovation and excellence was further cemented through this collaboration.

Conclusion

The story of the Shark is one of innovation, collaboration, and engineering excellence. Laird (Anglesey) Ltd. and SIF together created a vehicle that addressed a critical need in waste management, setting new standards for efficiency and durability. This historical partnership is a shining example of how two companies can synergize their strengths to create solutions that leave a lasting impact.

As we reflect on this remarkable achievement, it’s clear that the Shark was more than just a vehicle; it was a testament to the power of ingenuity and the enduring legacy of those who dared to think differently. Through the combined efforts of Laird and SIF, the streets of London—and indeed many cities—became cleaner and more efficient, proving once again that great things happen when expertise meets innovation.